X

wikiHow is a “wiki,” similar to Wikipedia, which means that many of our articles are co-written by multiple authors. To create this article, 17 people, some anonymous, worked to edit and improve it over time.

This article has been viewed 60,171 times.

Learn more...

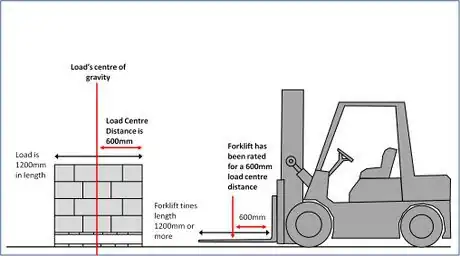

In working with forklifts, the concept of "load center distance" can be described as "the distance from the vertical face of the forklift tines to the load's center of gravity." For the purpose of this article, we will say the forklift in question is a counterbalance, and the load center distance it is rated to is 600mm.

Steps

-

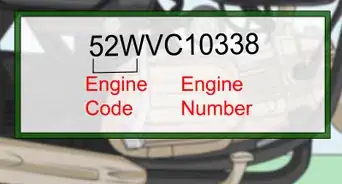

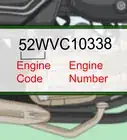

1Know how to find out your forklift's load center distance. All forklifts are rated by the manufacturer to a maximum weight capacity at a certain height and load center distance. All this information can be found on the Forklift's Data Plate. An example of how a data plate would read:

- Load Center Distance: 600mm

- Mast Vertical 2000kg

- Forward tilt 1000kg

- Height A: 5000mm.

- Therefore, from this information, the maximum weight the forklift can carry is 2000kg to a height of 5000mm, as long as the mast is vertical, or back tilt is applied.The load should have a maximum length of 1200mm (to make the load center distance 600mm)

-

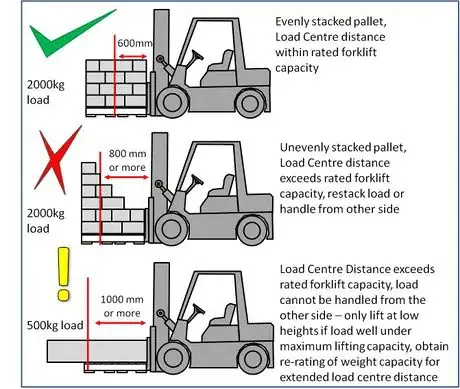

2Learn how to calculate load center distance of loads. In most cases, the load center of an evenly stacked pallet/"load" will be in the center of the load - using this information, if a load is 1200mm in length, then its load center will be at 600mm - correct for our forklift's load center distance rating.

- However a load on a pallet 1400mm in length will have a load center distance of 700mm which exceeds our forklift's rated load center distance - this load can only be picked up if is well under the maximum rated weight capacity of the forklift - some forklifts are rated for multiple load center distances, however, others may not be.

Advertisement -

3Consider unevenly stacked and irregular loads. These types of factors majorly affect load center distance, even if the load is 1200mm in length, if all the weight is stacked away opposite the forklift, then the load center distance of the load will be increased outwards, however a simple remedy is to simply pick up the pallet from the other side if possible, or re-stack - with standard loads such as boxes on a standard pallet it will be possible. However, for irregular loads such as machinery overhang on a pallet, it may not be possible - simply ensure it is well under the weight capacity and handle with care.

-

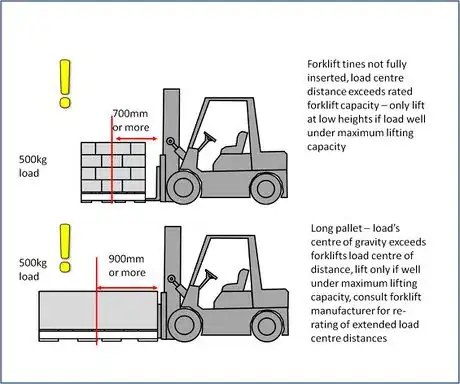

4Understand the effects of Long Pallets or Forklift tines not fully inserted. Two other common factors that can affect load center distance are the use of longer or irregularly sized pallets, or simply not inserting the forklift's tines all the way into a pallet before lifting. Both are sometimes unavoidable in forklift operations where different pallets are handled, or trucks are loaded, so both have to be managed by ensuring the loads stay well within the forklifts maximum rated capacity.

- If the forklift is constantly having to handle loads exceeding its load center distance, however, it will have to be re-rated by the manufacturer or an authorized forklift specialist to determine its maximum safe lifting capacity at extended load center distances.

-

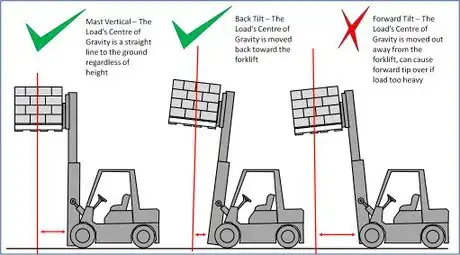

5Learn how tilt affects load center distance. A major factor often overlooked by newer and experienced forklift operators alike is the use of tilt and its ability to affect the forklift's load center distance. As previously mentioned on the forklift's data plate, the weight capacity of the forklift is halved when the forward tilt is used.

- This is because, while at ground level and low lifting levels, the use of tilt may indeed be negligible to affect the load center distance of the load, at height, tilt can greatly affect the load center distance, particularly forward tilt. By moving the load forward and away from the forklift, the load's center of gravity is now well beyond the recommended load center distance, so even when loads are within the forklifts maximum lifting capacity, forward tilt reduces the lifting capacity, and is the main factor in forward-forklift tip-overs, as operators are simply unaware of it.

- Back tilt on the other hand, reduces the load center distance (which is good for added stability). However it is usually not recommended to handle loads at full back tilt at high heights, since the load will need to be returned to mast vertical (level forks) before stacking, at height, moving the load at height with tilt can cause tip-overs or dropped loads if moved too quickly.

-

6Consider the use of attachments. All forklift attachments need to be approved for use by the manufacturer and/or a forklift specialist before use - this includes the re-rating of the forklift's lifting capacity when using different attachments due to the differing load centers among other factors. Some common forklift attachments that have a significant effect on the forklift's load center distance/lifting capacity include drum lifters (beak and claw or clamp) fork tine extensions ("slippers), carpet spikes and many more.

Advertisement

Community Q&A

-

QuestionWhen is it okay to use forward tilt?

Mzm555Top AnswererWhen picking up very low pallets/skids (with no bottom boards) off the ground, forward tilt can be quite helpful. When lifting, you should then apply back tilt until mast vertical or tilted back. Slight forward tilt can be used when stacking loads onto racking or onto each other, as it lets you see that the load is fully resting on the rack/load underneath before reversing out. Stacking with mast vertical is also ideal, but harder to achieve. Stacking with back tilt isn't particularly recommended, as the opposite side cannot be seen and may not be fully rested down on the rack/load underneath.

Mzm555Top AnswererWhen picking up very low pallets/skids (with no bottom boards) off the ground, forward tilt can be quite helpful. When lifting, you should then apply back tilt until mast vertical or tilted back. Slight forward tilt can be used when stacking loads onto racking or onto each other, as it lets you see that the load is fully resting on the rack/load underneath before reversing out. Stacking with mast vertical is also ideal, but harder to achieve. Stacking with back tilt isn't particularly recommended, as the opposite side cannot be seen and may not be fully rested down on the rack/load underneath. -

QuestionForks should be spaced how far apart?

Mzm555Top AnswererThe spacing of the forks won't affect your forklift's load center distance rating; however it will affect the stability of the load being carried on the forks. Set the forks too narrow and the load will be likely to fall off the forks sideways; set the forks too wide and you will need to be extremely precise when picking up loads. For handling pallets, ideally your forks should be spaced equally apart center to the carriage/backrest, around 10 inches out from each side. But really there is no exact measurement; the best rule is to space them just a bit less from as wide as you can have them for the pallets/loads you will be handling.

Mzm555Top AnswererThe spacing of the forks won't affect your forklift's load center distance rating; however it will affect the stability of the load being carried on the forks. Set the forks too narrow and the load will be likely to fall off the forks sideways; set the forks too wide and you will need to be extremely precise when picking up loads. For handling pallets, ideally your forks should be spaced equally apart center to the carriage/backrest, around 10 inches out from each side. But really there is no exact measurement; the best rule is to space them just a bit less from as wide as you can have them for the pallets/loads you will be handling. -

QuestionWhen load center is 535 mm, can I lift a load of 2450 kg up to 8 meters?

Mzm555Top AnswererIt depends on what kind of forklift you have. A load center of 535 mm is within the standard 600 mm load center distance for most counterbalance forklifts; however, for a 2450-kg load, a forklift with a 3500 kg - 4000 kg lifting capacity would be most recommended. You can then check the forklift's data plate to see if the lifting capacity is reduced when lifting up to 8 meters (as generally forklifts lifting capacities are often reduced by several hundred kg when lifting loads above 3 or 4 meters).

Mzm555Top AnswererIt depends on what kind of forklift you have. A load center of 535 mm is within the standard 600 mm load center distance for most counterbalance forklifts; however, for a 2450-kg load, a forklift with a 3500 kg - 4000 kg lifting capacity would be most recommended. You can then check the forklift's data plate to see if the lifting capacity is reduced when lifting up to 8 meters (as generally forklifts lifting capacities are often reduced by several hundred kg when lifting loads above 3 or 4 meters).

Advertisement

Warnings

- Never handle a heavy load at height with forward tilt. With heavy loads even within the "mast vertical" lifting capacity, it can easily cause the forklift to tip over forwards. With lighter loads, the load may simply slip off the forklift tines - both of these incidents happen because the load center distance is too great/exceeds the forklift's rated capacity.⧼thumbs_response⧽

- Avoid lifting loads with the forks not fully inserted. Not only does it increase the load center distance (thus reducing the overall lifting capacity), it also increases the risk of dropped pallets causing damaged goods. Some pallets bearing heavy loads may even break apart when lifted with the forks partially inserted⧼thumbs_response⧽

- The use of side-shift will not affect load center distance, however, it will change the load's center of gravity laterally (sideways) which can lead to sideways tip-overs of forklifts carrying heavy loads when side-shifted to either side - especially when turning fast, or turning with the forks raised.⧼thumbs_response⧽

Advertisement

About This Article

Advertisement