wikiHow is a “wiki,” similar to Wikipedia, which means that many of our articles are co-written by multiple authors. To create this article, 38 people, some anonymous, worked to edit and improve it over time.

There are 8 references cited in this article, which can be found at the bottom of the page.

wikiHow marks an article as reader-approved once it receives enough positive feedback. This article received 31 testimonials and 92% of readers who voted found it helpful, earning it our reader-approved status.

This article has been viewed 1,079,403 times.

Learn more...

If you've purchased a fiberglass kit, you'll need to know how to work with these materials — or else things are about to get a little messy. The first step is building your mold, and then you can move onto preparing your fiberglass cloth and working with the hardener. Using fiberglass and polyester resin is not an intimidating process when it's straightforward and simple; the details in this wikiHow guide will supplement your kit's instructions nicely, assuring quality results.

Steps

Preparation

-

1Purchase a "fiberglass kit." A kit should contain the poly (polyester) resin, hardener (catalyst), and cloth for structural strength. You can buy kits from home centers, department stores, or auto parts stores in various sizes depending on your project.

- What exactly is fiberglass? Fiberglass starts off as a liquid. This liquid is then extruded through tiny little holes, which turn it into thin strands of threads. These threads are coated with a chemical solution and bundled together to form rovings, or long bundles of fibre. Add a bit of resin and you have strong, durable, flexible fiberglass.[1]

-

2Think of a mold for your fiberglass. If you are making fiberglass for project, like a simple box, bowl, or other shape, you probably want to assemble a "mold" or "form" to make sure that your fiberglass, which starts off in liquid form, adheres to the right shape. If you find yourself doing a fiberglass repair on a boat or car, for example, consider taping off the repair site and apply the resinous fiberglass coating directly to the repair site.[2]Advertisement

-

3Use foam or pliable materials for molds with organic shapes. Blocks of styrofoam or polystyrene foam work best for objects that have curves or other non-linear forms. Simply cut or shave the foam into your desired shape, such as a fountain bottom, bird bath, or dome. Cover the material with wax paper, and use wax to seal and attach all joints, as well as for smoothing rough seams.

-

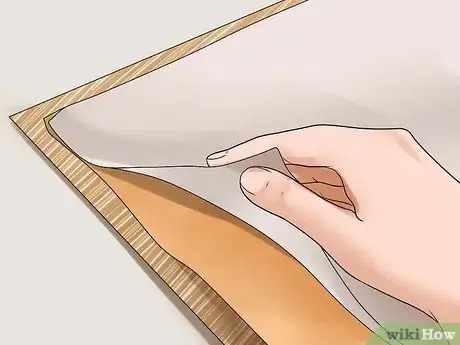

4Use cardboard, plywood, MDF, or other stiff materials for molds with linear or geometric shapes. These stiffer materials are best for large projects like dog houses or even boats. For these molds, cover the entire surface either with wax paper, or a good, even coat of paraffin wax. Carnauba wax can also be used as a substitute for paraffin wax.

-

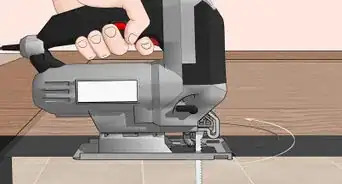

5Prepare the fiberglass mat or cloth in sheets cut to suitable sizes to cover your form, allowing for plenty of overlap where you need to join it at corners or sharp curves. The material will become very flexible when the resin is applied, so don't worry if you cannot get it to conform to an exact shape while it is dry.

Mixing and Application

-

1Measure an appropriate amount of resin in a metal container. A large can or metal bowl will work, but it should be of a disposable nature. Resin can be mixed in a clean plastic container, but because it generates heat when it sets, extreme care should be taken if you use one.[3]

-

2Add the hardener, according to package instructions. In a kit, you will have a pre-measured "can" or bucket of resin, and a pre-measured "tube" (like a glue tube) of hardener, so you can safely use an equal proportion of each material, i.e., half your hardener and half your resin, or some other proportion.

-

3Stir this material thoroughly, being careful to stir the bottom and sides, and not just the middle of the container, using a paint stick.[4]

-

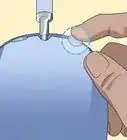

4Lay mat on or in your form, and spread the resin mixture over it with a disposable paint brush. The mat (or cloth) will seem to melt into the resin as you spread it,[5] and you can use the brush and additional coats of resin to build up the layer of fiberglass to a thickness of up to 1⁄4 inch (0.6 cm).[6]

- As you spread the resin over the fiberglass mat, make sure to apply it over corners and weak spots with the same coverage that you would over flat, easy-to-reach surfaces. If you fail to get good coverage in corners, for example, your fiberglass will eventually develop weaknesses in those corners.

-

5Work the mat and resin completely over your form until it is covered uniformly. Continue working until you have used all of your material.

Finishing

-

1Clean up any tools or spills with a solvent containing acetone before the material hardens. Acetone is great for cleaning up fiberglass because it's strong and evaporates quickly. Just be sure not to soak any portion of the fiberglass in acetone, and keep acetone away from any caulking, plastic, or rubber.[7]

-

2Repeat the steps of applying mat and resin until the finished project is as thick as you want it. Fiberglass is usually applied in layers until it is thick enough to give the required strength you desire to achieve. Depending on your project (leaving room for flexibility of course), try at least 3 layers, but no more than 10.[8]

- If possible, try laying down the fiberglass mat with the fibers oriented in different directions with each new layer. Fiberglass is strong across its axis but weak along its axis; if you can orient the strand mat so that its weak points are distributed along various axes instead of a single axis, you'll end up with much stronger fiberglass.

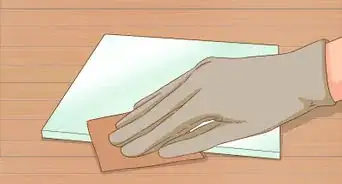

- Sand in between steps to eliminate rough spots where mat or cloth may project through the resin.

-

3Finish your project by coating with gel coat or a smooth coat of resin. Then, paint with a polyurethane or alkyd enamel, if desired.

-

4Remove your fiberglass from the form. If you have covered your form or mold with wax paper or paraffin wax, you should be able to peel the form from inside the shape, or peel the shape off of the form. The fiberglass will not stick to the wax.

Expert Q&A

-

QuestionHow do you get fiberglass white again?

Ahmed MezilAhmed Mezil is a Cleaning Specialist and the CEO of Hellamaid, a cleaning service operating out of Southern Ontario, Canada. With over four years of cleaning experience, Ahmed and his insured and bonded Hellamaid cleaning staff specialize in house cleaning, post-construction cleaning, commercial cleaning, deep cleaning, and disinfection cleaning on various home/building surfaces. Ahmed holds a BASc in Mechanical Engineering from the University of Waterloo, a MASc in Mechanical Engineering from the University of Toronto, and holds a Professional Engineering license in Ontario, Canada.

Ahmed MezilAhmed Mezil is a Cleaning Specialist and the CEO of Hellamaid, a cleaning service operating out of Southern Ontario, Canada. With over four years of cleaning experience, Ahmed and his insured and bonded Hellamaid cleaning staff specialize in house cleaning, post-construction cleaning, commercial cleaning, deep cleaning, and disinfection cleaning on various home/building surfaces. Ahmed holds a BASc in Mechanical Engineering from the University of Waterloo, a MASc in Mechanical Engineering from the University of Toronto, and holds a Professional Engineering license in Ontario, Canada.

Cleaning Specialist First you should identify the stains, since each problem will require different types of solutions. Most of the time, though, vinegar does the trick — you can mix it with baking soda or dishwashing liquid before wiping. Avoid using bleach at all costs, since it can cause more damage to the material itself.

First you should identify the stains, since each problem will require different types of solutions. Most of the time, though, vinegar does the trick — you can mix it with baking soda or dishwashing liquid before wiping. Avoid using bleach at all costs, since it can cause more damage to the material itself. -

QuestionWhy does paraffin wax need to be added to a mold?

Community AnswerThe wax will make it easier to remove the fiberglass from the mold. If you don't add the wax, the resin will glue your project to the mold.

Community AnswerThe wax will make it easier to remove the fiberglass from the mold. If you don't add the wax, the resin will glue your project to the mold. -

QuestionDoes fiberglass bond to rust?

Community AnswerDoing so is absolutely not recommended, without cleaning or repairing. But yes, if rust is covered with resin, allowed to dry and then fiberglass laid, it will bond.

Community AnswerDoing so is absolutely not recommended, without cleaning or repairing. But yes, if rust is covered with resin, allowed to dry and then fiberglass laid, it will bond.

Warnings

- Wear gloves and safety glasses when applying the resin, and avoid contact with skin.⧼thumbs_response⧽

- Do this project in a very well ventilated area.⧼thumbs_response⧽

- Polyester (fiberglass) resin produces significant heat when catalyzed, especially if too much hardener is used.⧼thumbs_response⧽

Things You'll Need

- Enough Fiberglass mesh to cover what you want it to do

- Fiberglass kit

- Disposable paint brush.

- Disposable gloves.

- Disposable mixing container.

References

- ↑ http://www.fibreglast.com/product/the-fundamentals-of-fiberglass

- ↑ https://www.youtube.com/watch?v=MAinuf5I_dw

- ↑ https://youtu.be/MifJ4WPMvqE?t=4

- ↑ https://youtu.be/MifJ4WPMvqE?t=88

- ↑ https://youtu.be/ujk-wBQDUSk?t=807

- ↑ https://youtu.be/ujk-wBQDUSk?t=705

- ↑ https://www.thehulltruth.com/boating-forum/125740-acetone-wash.html#b

- ↑ https://www.explorerforum.com/fiberglass/fiberglassing.htm

About This Article

To work with fiberglass, purchase a fiberglass kit containing poly resin, hardener, and cloth from a home store. Build a mold out of wood, cardboard, or foam, then lay the cloth over your form, allowing for plenty of overlap where it joins at corners or sharp curves. Measure your resin into a metal container, then add the hardener and stir thoroughly. Spread the resin mixture over the cloth with a disposable paintbrush until the form is covered uniformly, adding more layers as needed. Keep reading to learn how to create your mold!