This article was co-authored by Bess Ruff, MA. Bess Ruff is a Geography PhD student at Florida State University. She received her MA in Environmental Science and Management from the University of California, Santa Barbara in 2016. She has conducted survey work for marine spatial planning projects in the Caribbean and provided research support as a graduate fellow for the Sustainable Fisheries Group.

This article has been viewed 117,314 times.

Iron is a crucial metal in our world. It fuels the steel industries and allows blood to carry oxygen to our cells. It comes as no surprise that iron-containing compounds are of great interest. One such group of these compounds, called iron oxides, is formed by reacting iron and oxygen in some way. Which oxide you get depends on the specific circumstances under which the iron and oxygen react, and this will change the properties and uses of the resulting iron oxide.

Steps

Making Iron (II,III) Oxide (Magnetite)

-

1Locate a source of iron (III) (iron in the 3+ oxidation state). An iron (III) salt such as ferric chloride will be easy to add to the solution. It is often used for etching copper, so you can buy it online, at a chemical supply store, and sometimes even an electronics store. Also, a fine rust powder would work well. You can collect rust and grind it to a fine powder if you choose to go that route.[1]

-

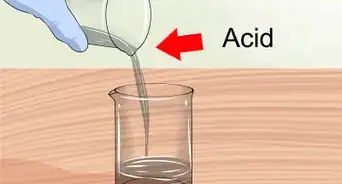

2Make a solution containing iron (III). Add water to the iron (III) oxide source in a beaker (or another glass container of similar size). The aqueous environment (in water) is ideal for the iron (III) and iron (II) molecules to react with each other and with oxygen. It will suspend your iron (III) molecules in solution and make it easy to combine with the iron (II) and oxygen molecules. You do not need to cover the container, but this can help keep out contaminants. [2]Advertisement

-

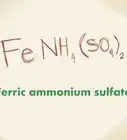

3Locate a source of iron (II) (iron in the 2+ oxidation state). Since iron (II) in its pure form is rare under atmospheric conditions, you will likely need to use an iron (II) salt. Iron sulphate, iron (II) chloride, and iron (II) phosphate are relatively common options. Iron sulphate is used in gardening and can be found at most garden supply stores.[3]

-

4Make a solution containing iron (II). Whatever your choice of iron (II) salt, you will need to dissolve it in water. Do this as a separate beaker (or other container) from the iron (III) solution to ensure that the iron (III) has not saturated the water. This will allow the most iron (II) to dissolve into the water. Again, a lid will help keep out contaminants, but is not necessary.[4]

- Wear gloves and goggles to protect your eyes and skin from any chemicals.

-

5Mix the solutions. Combine the iron (III) solution and the iron (II) solution into the same container. This will allow bringing the iron (III) ions and the iron (II) ions into contact with each other. They will also contact oxygen in the water and the atmosphere, which is needed to produce magnetite.[5]

-

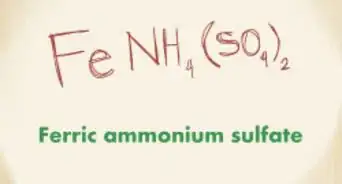

6Oxidize the solution. While the reaction will proceed by mixing the two solutions together, it will proceed very slowly. You can speed up the reaction by adding an oxidizing solution, such as ammonia. Hydrogen peroxide is also a good oxidizing agent.[6]

- The addition of an oxidizing agent will allow the reaction to proceed much faster. Times will vary based on the ratios of reactants and oxidizer, but you will likely see some change in just a few seconds.

- Use caution when working with hydrogen peroxide since it will create heat as it reacts with the water.

- Storing your iron oxide in a dry place is recommended.

Making Iron (III) Oxide (Rust) Using Electrolysis

-

1Obtain a source of iron. Aside from some salts, most iron compounds tend to be in the iron (III) state. This includes things like railroad rails, nails, steel wool, and paperclips. Choose your source based on the amount of iron you need, how fast you need it, and what is available to you. For example, steel wool is cheap and oxidizes quickly, but railroad rails contain a larger mass of iron.

-

2Fill a non-conductive container with water. You want to be sure that you have enough water in the container to cover the iron piece at all times. Keep in mind that the process of electrolysis may heat the water. This can increase the rate at which the water evaporates.[7]

-

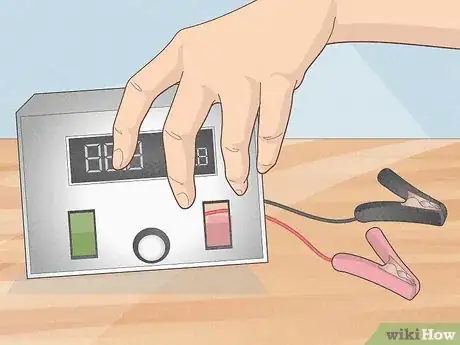

3Find a power source. You will need to use a battery or other direct current power source to power the reaction. The power source should have a lead connected to the negative side and a lead to the positive side. Choose the size of your power source based on how much rust you are trying to create and how fast you want it. Larger power supplies will generally create rust faster.[8]

-

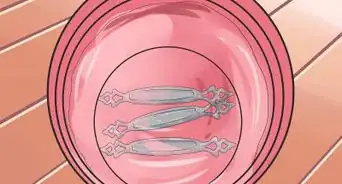

4Submerge the positive and negative leads. The leads should not touch each other. Instead, they should be submerged on opposite sides of your water tank. This will make the water solution part of the circuit and force electricity to flow through the water.[9]

-

5Submerge your iron source. While iron will typically rust under atmospheric conditions without any help, submerging it in water increases the rate of oxidation. Submerging iron in water that is being electrolyzed will increase the rate of oxidation even more since the electrolysis produces hydrogen gas (H2) and diatomic oxygen (O2). Diatomic oxygen is a great oxidizer and readily reacts with the iron to form rust.[10]

-

6Turn on the power. Now that your tank is set up, you can turn on the power. This will start the current flowing through the solution and oxidizing the metal. Be careful not to touch the leads, or touch them together. Also, do not put your hands in the water unless you turn the power off.

- If you are using a power source without a switch (like a battery), either put the leads in last, or do not hook the leads to the battery until you are ready for power.

-

7Allow to sit. While the reaction is relatively fast compared to natural oxidation, it isn’t instant. You will need to leave the reaction for several hours at least to yield rust. You will probably need to leave it for a day or two to get a decent amount.[11]

-

8Filter the solution. When your rust forms, it will be in the tank of water. The first step to getting it in a dry and usable form is to filter out some of the water. You can stretch cheesecloth or some other fabric over a jar or sink and pour the solution through. Allow it to sit for an hour or so to drain as much water as possible.[12]

-

9Dry the resulting rust. To finish drying your rust, you will need to bake it. Set your oven at 400 °F (204 °C) and bake the rust for one to three hours. Be sure to use an old pan, the rust will stain it.[13]

Making Iron (III) Oxide (Rust) Using a Strong Oxidizer

-

1Choose an iron source to oxidize. The more exposed surface area your source has, the better. For example, steel wool has a lot of surface area relative to its size, while a railroad rail has much less. Your oxidizer can only act on the surface of your iron.

-

2Choose an oxidizing agent. Bleach is a great oxidizing agent. Another good choice is hydrogen peroxide. A weaker oxidizing agent is salt water. The oxidizer you choose will determine how fast the iron is oxidized. The stronger your oxidizing agent, the faster your iron will oxidize.

-

3Expose the iron source to the oxidizer. You can submerge the iron source in the oxidizing solution. Another option is to spray the oxidizer on the iron at regular time intervals (every hour or so). Depending on how fast you want the reaction to proceed and how comfortable you are using strong oxidizers, you can dilute the oxidizer in water (this will weaken it and slow the reaction).

-

4Allow the reaction to proceed. Depending on your choice of oxidizer and exposure, this can take several hours or several days. You should certainly start to see rust forming within a week. If not, check to make sure you are using iron and that it is not coated with a protective layer such as wax.

-

5Collect and dry the resulting rust. You may have to scrape the rust off the surface of your iron piece to collect it. If you submerged the piece, you can filter the rust from the solution. If your rust is wet, dry it in an oven at 400 °F (204 °C) for one to three hours.

Making Iron (II) Oxide (Black Rust) by Burning Steel Wool

-

1Find a piece of plain steel wool. If the wool has any rust inhibitors or soaps on it, it will interfere with your results. You should also look for a steel wool with thin fibers. This will make it easier for the fibers to ignite and burn.[14]

-

2Place the steel wool on a fireproof surface. You will not be able to hold the steel wool in your hand. It will be on fire! You also do not want to burn anything down. Glass plates or tin lids are great choices.[15]

-

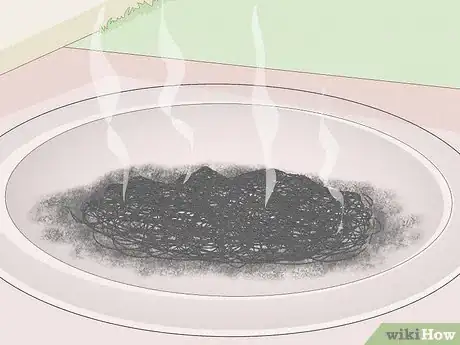

3Use a 9-V battery to ignite the steel wool. Touching a 9-V battery to the steel wool will connect the positive and negative leads of the battery. This closes the circuit and allows electricity to flow. The steel wool will ignite because more current is flowing through than it can handle, so it heats up until it reaches an ignition point.[16]

-

4Observe the black rust that is formed. Black rust is formed as a result of oxidation in an oxygen deprived environment. Since the steel wool is oxidized so rapidly in this reaction there is little time for enough oxygen to access the iron to form iron (III) oxide (red rust).[17]

Expert Q&A

-

QuestionCan I use brillo pads instead of steel wool?

Bess Ruff, MABess Ruff is a Geography PhD student at Florida State University. She received her MA in Environmental Science and Management from the University of California, Santa Barbara in 2016. She has conducted survey work for marine spatial planning projects in the Caribbean and provided research support as a graduate fellow for the Sustainable Fisheries Group.

Bess Ruff, MABess Ruff is a Geography PhD student at Florida State University. She received her MA in Environmental Science and Management from the University of California, Santa Barbara in 2016. She has conducted survey work for marine spatial planning projects in the Caribbean and provided research support as a graduate fellow for the Sustainable Fisheries Group.

Environmental Scientist Brillo pads are steel wool impregnated with soap so it will make it more difficult for the desired reaction.

Brillo pads are steel wool impregnated with soap so it will make it more difficult for the desired reaction. -

QuestionWill it really ignite?

Community AnswerNo, not without a component to receive the oxygen. If powdered aluminum is added, then it will create a redox reaction, releasing lots of heat.

Community AnswerNo, not without a component to receive the oxygen. If powdered aluminum is added, then it will create a redox reaction, releasing lots of heat. -

QuestionI am trying to make ferrofluid and was told to mix vegetable oil with iron oxide. Will this work?

Community AnswerThis would work, although true ferrofluid is not just iron oxide and vegetable oil.

Community AnswerThis would work, although true ferrofluid is not just iron oxide and vegetable oil.

Warnings

- Handle all chemical reactions, especially the oxidizers, with care.⧼thumbs_response⧽

- Always wear gloves.⧼thumbs_response⧽

- Always wear goggles.⧼thumbs_response⧽

- Mixing bleach with acids will produce toxic gas.⧼thumbs_response⧽

Things You’ll Need

- Piece of Iron

- Oxidizing Agent

- Water

- Filter

- Water Containers

- Power Source

References

- ↑ https://www.youtube.com/watch?v=U6lqX6i7mJA

- ↑ https://www.youtube.com/watch?v=U6lqX6i7mJA

- ↑ https://www.youtube.com/watch?v=U6lqX6i7mJA

- ↑ https://www.youtube.com/watch?v=U6lqX6i7mJA

- ↑ https://www.youtube.com/watch?v=U6lqX6i7mJA

- ↑ https://www.youtube.com/watch?v=U6lqX6i7mJA

- ↑ https://www.youtube.com/watch?v=4VspOqaJ3gc

- ↑ https://www.youtube.com/watch?v=4VspOqaJ3gc

- ↑ https://www.youtube.com/watch?v=4VspOqaJ3gc

- ↑ https://www.youtube.com/watch?v=4VspOqaJ3gc

- ↑ https://www.youtube.com/watch?v=4VspOqaJ3gc

- ↑ https://www.youtube.com/watch?v=4VspOqaJ3gc

- ↑ https://www.youtube.com/watch?v=4VspOqaJ3gc

- ↑ http://www.thenakedscientists.com/HTML/experiments/exp/burning-iron-igniting-wire-wool/

- ↑ http://www.thenakedscientists.com/HTML/experiments/exp/burning-iron-igniting-wire-wool/

- ↑ http://www.thenakedscientists.com/HTML/experiments/exp/burning-iron-igniting-wire-wool/

- ↑ http://www.thenakedscientists.com/HTML/experiments/exp/burning-iron-igniting-wire-wool/

About This Article

To make iron oxide, start by getting an iron source with as much exposed surface area as possible, like steel wool. Then, choose an oxidizing agent, such as hydrogen peroxide, bleach, or salt water. Next, submerge the iron source in the oxidizing agent and wait for it to yield rust, which can take anywhere from several hours to a week depending on the strength of your oxidizing agent. Once the rust has formed, filter it from the oxidizing agent, and dry it in a 400°F oven for 1-3 hours if it's wet. For information from our Science reviewer on how to make iron oxide by burning steel wool, scroll down!