This article was co-authored by wikiHow staff writer, Eric McClure. Eric McClure is an editing fellow at wikiHow where he has been editing, researching, and creating content since 2019. A former educator and poet, his work has appeared in Carcinogenic Poetry, Shot Glass Journal, Prairie Margins, and The Rusty Nail. His digital chapbook, The Internet, was also published in TL;DR Magazine. He was the winner of the Paul Carroll award for outstanding achievement in creative writing in 2014, and he was a featured reader at the Poetry Foundation’s Open Door Reading Series in 2015. Eric holds a BA in English from the University of Illinois at Chicago, and an MEd in secondary education from DePaul University.

There are 8 references cited in this article, which can be found at the bottom of the page.

This article has been viewed 10,102 times.

Learn more...

A duct detector is a special type of sensor that checks air ducts for smoke. They are important because they alert people that there’s a fire somewhere in a building and shut down the air flow in the ducts to prevent smoke from spreading. They are always installed on the outside of supply ducts, and the detector has an exhaust valve that sticks inside of the duct and checks the air inside for smoke. You can test a duct detector with a magnet, manometer, or canned smoke. These tests assess different parts of your duct detector, so they should all be performed at least once a year to ensure that your detectors are functioning properly. Besides, each test takes less than 5 minutes to perform and a functioning duct detector can save lives in the future.

Steps

Performing a Magnet Test

-

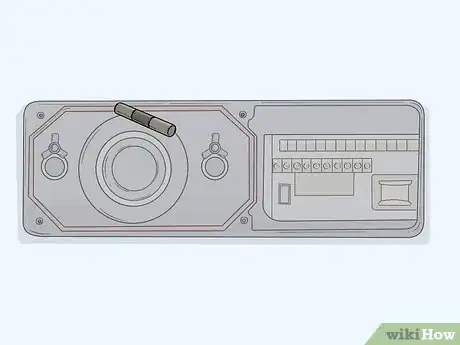

1Get a high-powered magnet to perform this test. While you may be able to do this with a weaker magnet, you’re better off using a high-quality neodymium magnet. Inside of your duct detector, there is a magnetic reed that trips and triggers the alarm sound. By tripping this magnetic reed intentionally, you can assess whether the smoke detector actually triggers correctly when it senses smoke.[1]

- Perform this test at least once a year to ensure that the alarm system is working. You should also complete this test if you ever replace any electrical components in the detector.

- A test magnet for your specific model often comes with a duct detector when you purchase it.

-

2Put your test magnet against the circular sensor on the detector. The circular sensor is the large circle sticking out of the front of your detector. If you’re struggling to find it, there are two 1–2 in (2.5–5.1 cm) openings for air flow symmetrically placed on either side of the sensor. Hold the magnet against the sensor, just above the blinking light on the bottom of the sensor’s frame.[2]

- If there is some kind of plastic case on the detector, pry it off or unscrew it to access the body of the duct detector.

Tip: If there are no blinking lights on the duct detector, your detector isn’t on and will not fire. There is something wrong with the electrical components if it isn’t on but it’s hooked up correctly. Consult a an electrician that specializes in smoke detectors or fire alarm systems to diagnose these problems.

Advertisement -

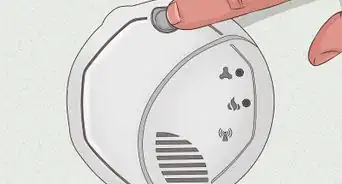

3Hold the magnet in place for 5-10 seconds until the alarm goes off. Keep the magnet still and wait 5-10 seconds. If the detector is working properly, the magnet will trick the magnetic reed inside of the sensor to trigger and the beeping alarm sound should fire. If it does, your detector is operating correctly. If it isn’t, you have a faulty sensor and have to replace your duct detector.[3]

- If the alarm doesn’t sound, try holding the magnet around other parts of the sensor. Your magnetic reed may have been installed somewhere else in the sensor. It’s almost always at the bottom near the blinking red light, though.

- Reset your duct detector after tripping the alarm. To do this, press the “Reset” button on the fire alarm control panel. This panel is usually in a building’s boiler room or electrical closet.

Using a Manometer

-

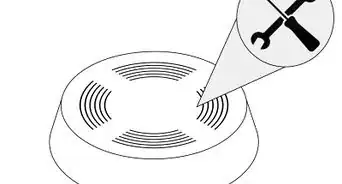

1Get a manometer to test the differential pressure in the exhaust tube. Even if a duct detector is triggering properly, it won’t go off if there isn’t any air coming in from the duct. To make sure the detector is checking the air, get a manometer. The exhaust tubes on the detector are designed to fit the probes on a manometer, so you don’t need any additional hardware to complete this test.[4]

- Differential pressure refers to the pressure inside of a space relative to the space around it. In this case, you’re testing the air flow inside of the smoke detector based on the air being pumped through the duct it’s attached to.

- Perform this test at least once a year to ensure the detector can sense smoke.

-

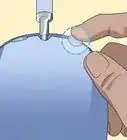

2Plug the probes into the air valves next to your detector’s sensors. The sensor is the big circular object protruding from the front of the duct detector. To the left and right sensor, there are 2 small openings called air valves. Plug each test probe into the metal piece sticking out of the manometer. Then, push 1 probe into the opening on the left and the other probe into the opening on the right.[5]

- It doesn’t matter which probe goes into which valve.

- Unscrew or pry off any plastic cases that are attached to your duct detector before doing this.

-

3Press the “Test” or “Dif” button on the manometer and read the results. To run your test, turn the manometer’s power on by pressing the power button. Then, press “Test” or “Dif” to run your differential pressure test. So long as your results are between 0.01 and 1.2, your detector is receiving enough air to register smoke in the duct.[6]

- A reading of 0.00 indicates that there is no air flow. Since this is impossible, your manometer is likely not functioning correctly.

Tip: If the number exceeds 1.2, your exhaust tube isn’t receiving enough air so the exhaust tube that’s sticking in the duct is either blocked or installed improperly. Remove the duct detector from the wall and check the shorter pipe to see if it’s blocked. If it isn’t, install a new exhaust pipe.

Testing with Smoke

-

1Get a can of aerosol smoke to test your duct detector. Aerosol smoke, also known as canned smoke or fake smoke, is a can filled with odorless, simulated smoke. It is designed specifically to test smoke detectors. The smoke inside isn’t real, so it won’t leave any residue or odors behind, but the fake smoke will function the same way that regular smoke will. This test assess whether your duct detector’s sensor responds appropriately to the presence of smoke.[7]

- Perform a smoke test to diagnose the detector’s functionality at least once a year.

Tip: You can use actual smoke if you prefer. A lit cigarette or stick of incense will do the trick if you don’t mind adding some odors to the building or can’t pick up some canned smoke.

-

2Pull the funnel out of the top of the can. To ensure that the smoke rises vertically, there is usually a funnel built into the top of the can. To open this funnel, pull the top of the can upwards or swing the can away from you like you’re swinging a baseball bat to force it out.[8]

- Some cans of aerosol smoke use a nozzle that is similar to spray paint. These devices are less desirable since forcing air directly on the detector can force the reed to trip and you won’t know for sure whether the air or the smoke forced the smoke trigger the alarm.

-

3Spray the can 3–6 ft (0.91–1.83 m) beneath the duct detector to trip it. Stand directly underneath the duct detector and hold the can with the funnel pointed directly above you. Keep the can 3–6 feet (0.91–1.83 m) away from the detector and pull the trigger on the can for 3-5 seconds. If the alarm goes off, your duct detector is working just fine. If it doesn’t, the sensor is not reading the air correctly.[9]

- If the alarm doesn’t go off, the sensor inside of your duct detector is not working properly and the sensor must be replaced.

- Reset your fire alarm system by pressing the “Reset” button on the control panel after performing this test.

Things You’ll Need

Performing a Magnet Test

- Test magnet

Using a Manometer

- Manometer

- Test probes

Testing with Smoke

- Canned smoke

References

- ↑ https://www.systemsensor.com/en-us/Documents/Duct_Detector_Testing_Maintenance_Flyer_HVFL184.pdf

- ↑ https://youtu.be/zpnHZevItyw?t=80

- ↑ https://www.systemsensor.com/en-us/Documents/Duct_Detector_Testing_Maintenance_Flyer_HVFL184.pdf

- ↑ https://youtu.be/m--TC0zokiY?t=353

- ↑ https://youtu.be/m--TC0zokiY?t=368

- ↑ https://youtu.be/m--TC0zokiY?t=374

- ↑ https://www.systemsensor.com/en-us/Documents/Duct_Detector_Testing_Maintenance_Flyer_HVFL184.pdf

- ↑ https://youtu.be/TGIazwYowTg?t=99

- ↑ https://youtu.be/TGIazwYowTg?t=180