This article was co-authored by Ryaan Tuttle. Ryaan Tuttle is a Home Improvement Specialist and the CEO of Best Handyman, Inc. in Boston, Massachusetts. With over 17 years of experience, he specializes in building home service businesses, focusing on creating scalable and efficient brands. With the help of his global team, the companies have achieved over 10+ million in sales and received recognition through magazine features, and enjoy partnerships with wikiHow and Jobber field service software. Boston Magazine and LocalBest.com have named Best Handyman Boston the Best Handyman in Boston. Ryaan holds Construction Supervisor and Home Improvement Contractor Licenses.

wikiHow marks an article as reader-approved once it receives enough positive feedback. In this case, 89% of readers who voted found the article helpful, earning it our reader-approved status.

This article has been viewed 616,540 times.

Broken or stripped screws bring projects to a screeching halt. Anyone who does DIY work encounters this problem eventually, so having a screw extractor saves you a lot of time. The extractor is similar to a screw but has a reversed thread. To use it, you drill into the center of the screw, place the extractor inside, and turn it counterclockwise. When the screw comes out, you’ll be able to return to your project right away.

Steps

Getting the Screw Ready

-

1Put on safety gear. Using a screw extractor involves drilling into metal. The last thing you want is a flying shard of metal in your eye. Wear safety goggles made with polycarbonate lenses.[1]

-

2Align a center punch over the screw. A center punch is a metal cylinder that looks like a pen. You can find them at any hardware store. With one hand, hold the metal tip against the center of the screw head.Advertisement

-

3Indent the screw by hammering in the punch. Pick up a hammer in your free hand and use it to tap the top of the punch. Strike it very lightly. If you did it right, you’ll see a small divot in the screw. This guides your drill bit into the center of the screw.

- If the screw is in a tight space, use a small metal drill bit and a right angle drill. Be careful that the bit doesn’t slip while you’re drilling.

-

4Apply a drop of thread cutting oil to the screw. Thread cutting oil is sold in big jugs at hardware stores, but you only need a drop. Tip the bottle over to splash a little bit onto the screw head. Cutting oil lubricates the metal, which means less time spent drilling and less wear and tear for your drill bit.

- If you don’t have this oil, you can try a drop of motor oil, WD-40, or another lubricant. Household oils will help but offer less protection to the drill bit.

-

5Add a drop of penetrating oil to rusty screws. Penetrating oil is needed for rusted screws or ones attached to metal surfaces. It loosens the screw, making it easier to remove. Add a drop of it onto the screw head on top of the thread cutting oil.

- If you don’t have penetrating oil, acetone may work too.

Drilling the Screw

-

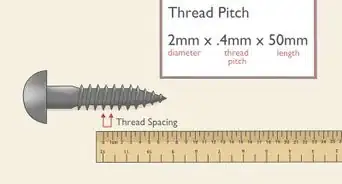

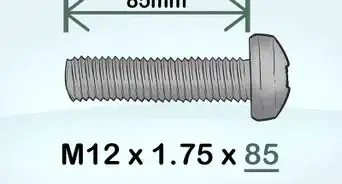

1Select a drill bit slightly smaller than the screw. Hold the drill bits up to the screw or fastener you need to remove. The right one will be slightly less wide than the screw head. When you find the right one, attach it to your drill.[2]

- You can buy individual drill bits from hardware stores at a small cost or buy a whole set with varying sizes.

-

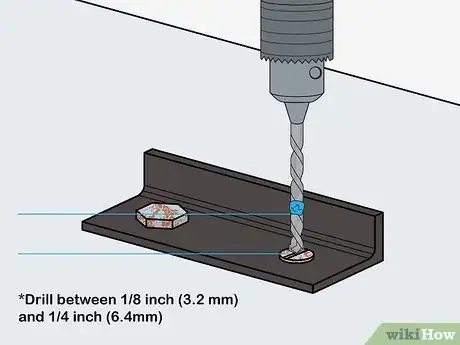

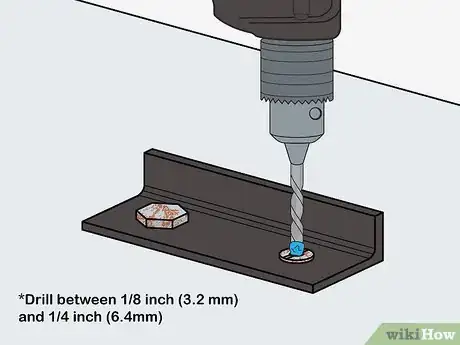

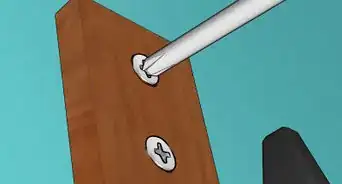

2Line the drill bit up with the center of the screw. Place the drill bit in the divot you created earlier. Move slowly as you begin to drill. Too much force will damage the screw. Focus on holding the drill bit steady so it drills straight down into the screw head.[3]

-

3Drill a hole for the extractor. You will need to drill somewhere between 1⁄8 inch (3.2 mm) and 1⁄4 inch (6.4 mm) into the screw head. The depth depends on the screw extractor you have. Hold up the extractor to compare it to the hole you drilled. If the extractor doesn’t fit, keep drilling to widen the hole.[4] [5]

- Make sure the drill bit only drills inside the screw or else you could damage the threads.

Pulling out the Screw

-

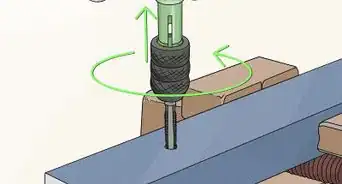

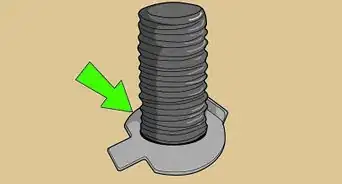

1Insert the extractor into the drilled hole. The spiral end of the extractor goes into the hole. You can tap it with a hammer to make sure it’s in there, but don’t force it. The loose end should have a tap handle, which looks like a T, for you to hold onto. Twist the extractor counterclockwise until you can’t turn it anymore.[6] [7]

-

2Twist the extractor with a wrench or drill. Grip the top of the extractor with a wrench. Continue to twist it counterclockwise until the screw pops free. Many extractors are designed to work with drills. Attach the free end of the extractor to the drill and turn on the drill to turn the screw counterclockwise. It’ll come out without much resistance.[8]

- When using the extractor with a drill, make sure the drill is set to rotate in reverse!

- If the screw is stuck, rigorously twist the extractor in both directions to break it loose.

-

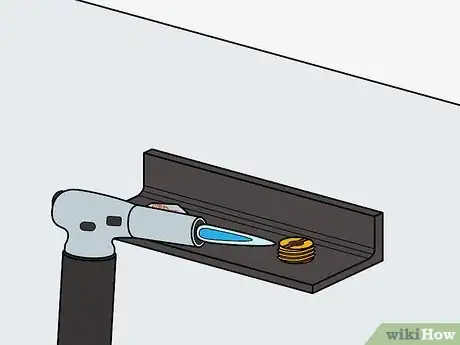

3Heat the screw if it is stuck. If you have a propane or butane torch, lightly heat the screw for a minute or two. This can only be done if you’re working with non-flammable materials such as metal. Try the screw extractor again. The heat expands the metal, making it easier to pull out.

-

4Pull the screw out with pliers. Regular pliers may work, but clamping pliers keep a better grip on the screw. Twist the screw and try to pull it out. Heat also helps here in making the screw easier to pull out.[9]

- You might also be able to drill further into the screw to weaken or break it. Be careful to avoid damaging the material around the screw.

- Screw-extracting pliers can be purchased at your local hardware store and are meant for removing screws.

Community Q&A

-

QuestionCan you use this procedure if screw is just rusted into metal shower door frame?

Community AnswerYes, use penetrating first. Penetrating oil loosens the rust. Then you should be able to drill the screw.

Community AnswerYes, use penetrating first. Penetrating oil loosens the rust. Then you should be able to drill the screw. -

QuestionThe meager instructions included with my Yamo screw extractor kit imply that I first drill a hole using the drill bit, but drill counter clockwise. Is this correct?

Community AnswerThere are two kinds of extractors. 1. Self drilling extractors that you simply use on the screw in a reverse direction and it will drill + extract. 2. (The kind you have) where you drill a hole, normally as you would, and then you extract with the extractor in a reverse direction so that it pulls the screw out.

Community AnswerThere are two kinds of extractors. 1. Self drilling extractors that you simply use on the screw in a reverse direction and it will drill + extract. 2. (The kind you have) where you drill a hole, normally as you would, and then you extract with the extractor in a reverse direction so that it pulls the screw out. -

QuestionHow do I extract the threaded remnant of a screw that broke inside something?

Community AnswerYou could epoxy a small rod or weld it on and twist it out. But depending on what material you're working with, it could be tricky.

Community AnswerYou could epoxy a small rod or weld it on and twist it out. But depending on what material you're working with, it could be tricky.

Warnings

- Always wear safety goggles when drilling into metal.⧼thumbs_response⧽

- Don’t force the extractor. If the screw feels stuck, stop so the extractor doesn’t break inside it.⧼thumbs_response⧽

- Remember to work slowly and use as little pressure as possible on the screw. Damaging the screw or extractor makes the situation a lot worse.⧼thumbs_response⧽

Things You'll Need

- Safety glasses

- Power drill

- Drill bits

- Center punch

- Hammer

- Screw extractor

- Thread-cutting oil

- Penetrating oil for rusted screws

- Wrench

References

- ↑ https://www.bobvila.com/articles/how-to-use-a-screw-extractor/

- ↑ https://www.bobvila.com/articles/how-to-use-a-screw-extractor/

- ↑ Ryaan Tuttle. Home Improvement Specialist. Expert Interview. 18 June 2021.

- ↑ Ryaan Tuttle. Home Improvement Specialist. Expert Interview. 18 June 2021.

- ↑ https://www.bobvila.com/articles/how-to-use-a-screw-extractor/

- ↑ Ryaan Tuttle. Home Improvement Specialist. Expert Interview. 18 June 2021.

- ↑ https://www.youtube.com/watch?v=K34RS6M11uw&feature=youtu.be&t=227

- ↑ https://www.youtube.com/watch?v=QK32YsQNss8&feature=youtu.be&t=175

- ↑ https://dengarden.com/home-improvement/How-to-remove-a-broken-or-stripped-screw

About This Article

To use a screw extractor, first align a center punch over your screw and hammer the punch to make an indentation to guide your drill bit. Then, attach a drill bit that’s slightly smaller than your screw to your drill. Next, put the drill bit in the indentation you made and drill ⅛ to ¼ of an inch into the screw head. When you’ve drilled a hole big enough for your screw extractor, put the spiral end of your extractor in the hole and twist it counterclockwise until it won’t go any farther. Finally, continue twisting it with a wrench until your screw pops loose. To learn how to use thread cutting oil or penetrating oil to make using your screw extractor easier, read on!