This article was co-authored by wikiHow Staff. Our trained team of editors and researchers validate articles for accuracy and comprehensiveness. wikiHow's Content Management Team carefully monitors the work from our editorial staff to ensure that each article is backed by trusted research and meets our high quality standards.

There are 7 references cited in this article, which can be found at the bottom of the page.

This article has been viewed 14,107 times.

Learn more...

Ah, the good ole miter saw. It’s always there when you need it, but if it’s cutting crooked, you may need to make some adjustments to keep it cutting properly and accurately. Fortunately, it’s actually a lot more simple than you may think. With the proper tools and the right approach, you’ll have your saw adjusted in no time. We’ve answered a few common questions that folks have about adjusting their saws to make the job even easier for you.

Steps

How do you adjust a miter saw blade?

-

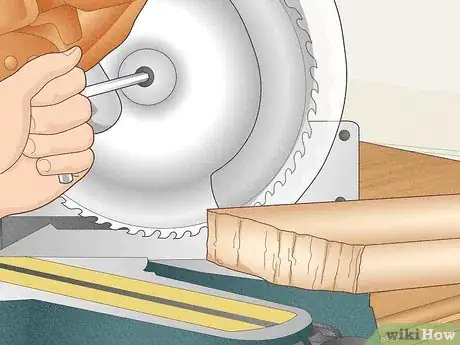

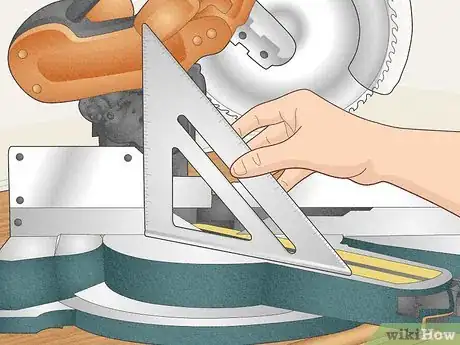

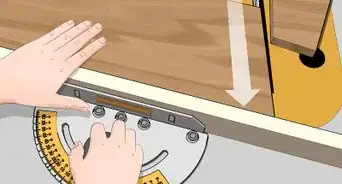

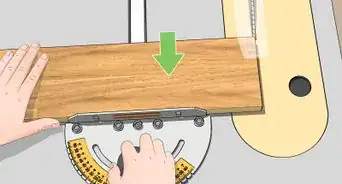

1Use a speed square to see if the blade needs to be adjusted. A speed square is a super handy triangular marking tool often used by carpenters. First, disconnect the power from your saw and place the speed square upright on the table so its edge is even with the opening the saw blade fits into when it’s lowered all the way down. Be careful to avoid the blade's teeth.[2] Then, lower the blade down to the table and move the speed square against the side of the saw blade. Look for a gap at the bottom edge of the speed square. If you see one, it means the saw blade isn’t square and needs to be adjusted.[3]

- If there isn’t a gap and your saw isn’t making even cuts, the problem could be the saw blade itself, an unstable fence, or another problem.

-

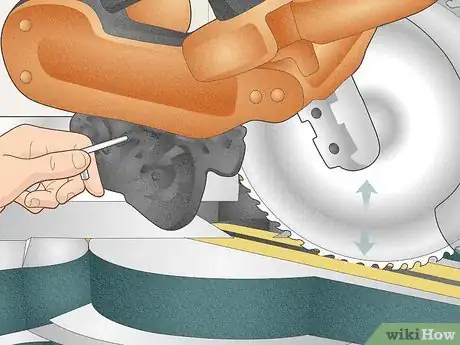

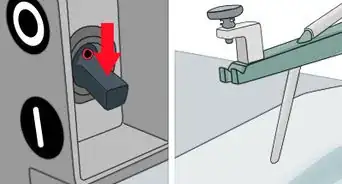

2Loosen the bevel handle and adjust the blade to contact the speed square. Locate the bevel handle at the back of the saw. Loosen the handle enough to allow you to move the blade around. Hold a speed square upright on the table with its edge lined up with the opening the saw blade fits into. Move the blade until it makes complete contact with and is flush against the speed square to adjust it. Then, tighten the bevel handle to secure it and you’re all set.[4]

- The blade shouldn’t be loose at all. If it is, try tightening the bevel handle some more.

Community Q&A

-

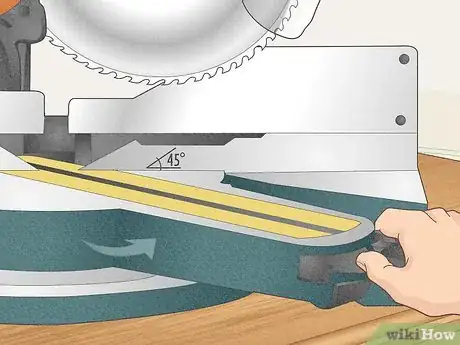

QuestionWhen my chop saw is set on 0, it is cutting at a slight angle. How do I fix that?

Imtiaz NabiCommunity AnswerIt is possible for chop saws to have zero error. You will need to calculate the error first using a woodworking speed squares or something similar to calculate the angle first. After that, adjust the saw slightly off that angle to compensate for the error. This is the best, and easiest solution.

Imtiaz NabiCommunity AnswerIt is possible for chop saws to have zero error. You will need to calculate the error first using a woodworking speed squares or something similar to calculate the angle first. After that, adjust the saw slightly off that angle to compensate for the error. This is the best, and easiest solution. -

QuestionIf I move the blade across the wood, it follows my line perfectly, but with the blade running, it moves off to the right away from my line by 3 or 4mm.

imtiaz nabiCommunity AnswerConsider clamping your work piece, as sometimes the vibration produced during the job can cause such errors.

imtiaz nabiCommunity AnswerConsider clamping your work piece, as sometimes the vibration produced during the job can cause such errors.

Warnings

- Always make sure the saw is unplugged before you make any adjustments. Remember to also check your saw's safety manual for more specific information regarding your model.[12]⧼thumbs_response⧽

References

- ↑ https://toolsowner.com/miter-saw-not-cutting-straight

- ↑ https://sawsonskates.com/how-to-adjust-a-miter-saw-for-accurate-cuts/

- ↑ https://www.thisiscarpentry.com/2010/07/23/miter-saw-tune-up/

- ↑ https://www.thisiscarpentry.com/2010/07/23/miter-saw-tune-up/

- ↑ https://images.homedepot-static.com/catalog/pdfImages/24/2401c477-4428-4f12-b5e9-c18c1ecfbe98.pdf

- ↑ https://www.scu.edu/media/school-of-engineering/pdfs/maker-lab-resources/Manual_CraftsmanCompoundMiterSaw.pdf

- ↑ https://sawsonskates.com/how-to-adjust-a-miter-saw-for-accurate-cuts/

- ↑ https://www.thisiscarpentry.com/2010/07/23/miter-saw-tune-up/

- ↑ https://www.protoolreviews.com/news/how-to-calibrate-a-miter-saw/34905/