wikiHow is a “wiki,” similar to Wikipedia, which means that many of our articles are co-written by multiple authors. To create this article, 31 people, some anonymous, worked to edit and improve it over time.

This article has been viewed 308,520 times.

Learn more...

Welders help build the world. In fields from construction to car racing to manufacturing, welders use their skills to fuse metal together to the proper specifications and strength. If you're interested in learning to become a welder, there are several ways to build the skills you'll need in the workplace.

Steps

Learning to Weld

-

1Understand the demands of the job. Commercial welders must be physically and mentally fit, with excellent hand-eye coordination, and the ability to stay focused on a repetitive task for long periods of time. The clumsy and careless need not apply. Welders take serious pride in their work and in the skills required to complete a job properly.

- A good welder also needs to be self-motivated and a self-starter, since part of the job might involve freelancing, finding your own projects and jobs. Welders can be in high demand, but it'll be up to you to seek out that demand and find the jobs that require a good and knowledgeable welder.

- As a welder, you'll be around hot metal, bright lights, and noxious fumes every day. In many welding jobs, you will be working around heavy equipment that can cause serious injury. It is imperative to gain some understanding of all of the potential dangers possible prior to embarking upon a pursuit of welding certification and employment.

-

2Research welding training programs near you. If you don't have any experience welding on-the-job, finding a training program is the best way to get started. Many community colleges have welding programs, as do adult vocational programs and trade schools. These are the most reliable way to get into the industry, and a good program will include job placement assistance to help you get a foot in the door. The American Welding Society (AWS) provides a searchable database of welding schools found here.

- In the United States, the three most prestigious private welding schools are the Tulsa Welding School, the Hobart Institute of Welding Technology, and the Lincoln Welding School.[1]

- Scholarships are available on the AWS scholarship page on their website. Many companies and unions will also provide scholarships, as many regions have a shortage of welders and both types of organizations have an interest in training more.

Advertisement -

3Get some basic experience welding. You can't learn welding from a book. Welding is a hands-on trade that you can only learn by taking an introductory-level class, signing up for an apprenticeship program that will give you on-the job training, or enrolling in a welding school and building the skills necessary to weld metal.

- If you've got no experiencing welding, or have some informal training from tinkering around at home and you want to learn more, start by taking an introductory welding course at a community college or tech school in your area to learn about the safety skills required and the mechanics of the job, then practice on your own as much as possible.

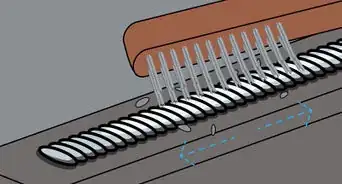

- Learn to strike an arc, tack, and control your puddles. You've got to start somewhere, and the first essential skills in welding are in making small welds, called tacks, to get the metal to stick together without clamps to hold it, and then accurately controlling your arc and wire or rod feed as you connect the pieces. It'll take some practice and guidance, so seek out experienced welders to show you the ropes when you're first getting started.[2]

- Many industrial welding jobs these days are done with flux core welding machines, which automatically unspool wire, making jobs much easier and more efficient. If you want to get experience welding and getting paid for it, practice this kind of welding, which will be one of the most common type of work you'll encounter.

-

4Learn which types of welding you'll need for specific jobs. Welders are needed for many different tasks, and some industries or types of job use certain kinds of welding more than others. Learn the basic types, and if you're aiming for a specific industry, learn the correct type:

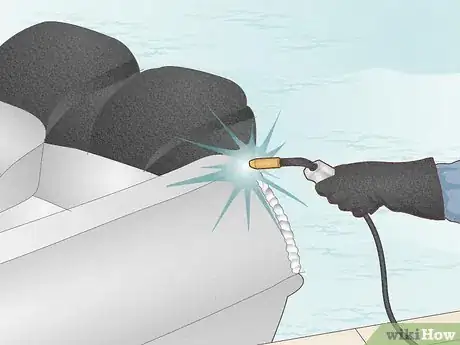

- MIG welding, or metal inert gas welding, is commonly used to fabricate steel, stainless steel, and aluminum. The automotive industry, shipyards, and many other industries use MIG welding, increasingly the flux-cored variety.

- Stick welding, also called Shielded-Metal Arc Welding, is a simple and popular type of welding due to its low cost and ease of use. It is often used in construction jobs and in home projects.

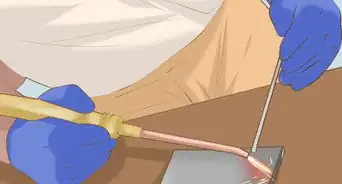

- TIG welding, or tungsten inert gas welding, is a slow process that requires clean metal. However, it can make a high quality weld for almost any metal. Architectural fabrication shops often use TIG for stainless steel welding. TIG welding is considered high-skill, so if you train in TIG and find a place that uses it, you'll increase your chance at a job.

- There are many more varieties of welding which tend to be less common than the three above. Some of these, such as Gas Tungsten-Arc Welding, are highly specialized and only used in a few fields, such as bicycle and airplane manufacturing.

-

5Participate in an apprenticeship program. Many companies offer on-the-job training through apprenticeship programs, where you'll be doing entry level welding work but hopefully have the chance to learn more. As you complete more hours in apprenticeship programs, your level of accreditation will rise.

- Typically, fully completing your apprenticeship and rising to "journeyman" rank takes around three years. However, this varies widely by region, even within the same country in the case of United States and Canada.

- Some areas of the world may not have a formal apprenticeship program at all, but on the job training programs will still help you land a job when you're not yet an experienced welder, and gain the skills you need to qualify for more advanced jobs.

- Find programs with job placement assistance. A good welding program should assist its students in finding a job once the program is complete. Preferably, your program should include opportunities to meet potential employers.

Getting the Proper Certifications

-

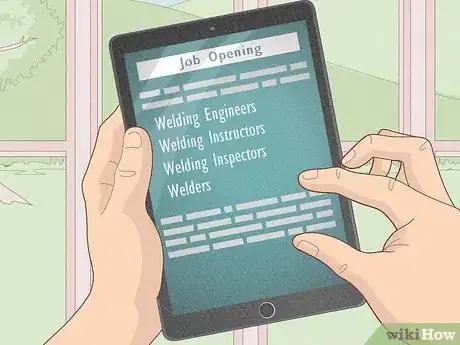

1Learn about the different types of employment available to welders. Like any job, it's important to understand the difference between what will be expected of you as an entry-level welder and what will be expected of you in other welding openings for jobs you might find advertised for welders. The type of experience and certifications you'll need will vary, depending on the type of position you want to pursue.

- Welders do one thing–weld metal. Good welders can consistently find work in all types of manufacturing, performing their trade skill in the making of cars, ships, heavy machinery, and other essential items. If two pieces of metal need to be fused together, the welder is the person for the job. The welder doesn't usually assemble the metal to be welded, operate any other kind of machinery, or do anything but weld. Fitters, erectors, operators, and other trades are often involved in processes that require welding.

- Welding engineers have more responsibilities, including project management and planning, metallurgy, and overseeing the welders. Welding engineers usually need experience drafting in CAD, and are generally required to have a four-year degree in materials engineering or welding engineering, and often an advanced degree.[3]

- Welding Instructors must have passed the Certified Welding Instructor certification examination from the AWS, becoming certified to instruct others in the skills necessary to weld. If you have ambitions to teach, many jobs are available for qualified instructors. You need several years of experience with different styles of welding to qualify for this certification.

- Welding Inspectors are certified to evaluate and complete quality standards commensurate with the standards of the AWS. On-the-job experience and working alongside a Senior Welding Inspector are required before completing the certification.[4]

-

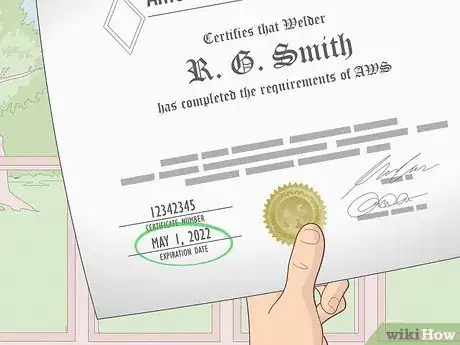

2Get the appropriate AWS certification. Typically, AWS certification involves a welding test and a written exam that you'll take every six months to a year, depending on regional requirements, to keep your certification up to date. You'll need to obtain the certification necessary for the welding discipline pursued.

- In commercial welding, welders often need to complete the AWS GMAW or MIG 3G certification, which is a basic skills test in a variety of different physical positions. Further certifications may be necessary, depending on the skills required for a particular job. This certification allows a welder to take the title "Certified Welder," opening up a variety of job opportunities.

- Welding engineers must complete their Welding Engineer AWS Certification, which covers a variety of practical topics, fundamental techniques, and some geometry. With the completion of this test, the welding engineer becomes a Certified Welding Engineer (CWE).[5]

- In some areas, including certain U.S. states, you can start working as a welder without certification, but unless you have excellent job experience, you'll have a hard time competing with people with training certification.[6] The Catch-22 is that it can be difficult to qualify for the exam without experience, but you can make up for that by attending school or an apprenticeship program.

-

3Pursue other skills that complement your welding. If you aspire to be an engineer, learn to read blueprints, oversee projects, and manage staff to make yourself the roundest, most marketable candidate for new jobs. If you never attended a welding training program, or the program didn't teach you certain skills, try to study them on your own, or ask friendly coworkers for basic training.

- Even if the job you're currently working doesn't require you to learn TIG welding, or some other skill you haven't yet acquired, consider learning more along the way to make yourself available for more jobs. The more styles of welding you know, the more variety of jobs you're able to perform.

Finding Welding Jobs

-

1Apply at a variety of locations. Many different industries will hire welders, and the jobs you're applicable for will vary depending on your experience and your level of certification.

- For most jobs, you'll need to provide a resume, proof of your certification, and pass a drug screen before being hired.

-

2Keep your certification up to date. Stay on top of your AWS certification's expiration date and complete the recertification procedure as soon as possible. This can have an effect on your pay, in some jobs.

- If you're lucky enough to be hired on somewhere full-time, you'll probably have to go through regular re-certifications and new on-the-job training programs. Fortunately, this will probably come with a raise in your pay grade, and new skills.

- To make yourself the most marketable candidate for each job, it's important to stay certified and actively seek new certifications to up your pay grade and your marketability for new projects and responsibilities.

-

3Research more specialized welding jobs and the requirements of specific jobs. If you know you are interested in a specific type of welding, or an industry that requires a specific type of welding, you may need more training to attain the skills necessary to do a more diverse range of jobs.

- Common welding jobs take place in shipyards, factories, construction sites, and along pipelines, although there are many more specialized options as well. If you're interested in a particular industry but aren't sure of the requirements, simply look at job postings online or talk to someone employed in that field.

-

4Work a variety of jobs if possible. Once you are an experienced welder with 10 – 20 years in the field, you'll probably have no problem finding steady, well paying employment. The more work you do until that point, in as wide a variety of welding jobs as you can, the quicker you'll learn the various techniques and types of welding in a practical setting.

- Consider applying to jobs that require travel. If you cannot find steady employment nearby, look for jobs further away. Many welders travel between jobs, as the largest jobs that require the most welders tend to only last a few months. Some people work for a company that gives them several months on the road followed by several months off.

Community Q&A

-

QuestionHow long does a license last?

Community AnswerAn American Welding Society certification lasts 6 months. You can renew your license every six months if you have documentation saying you've been consistently welding using the same method you tested under. If you cannot renew your license at any point, it expires.

Community AnswerAn American Welding Society certification lasts 6 months. You can renew your license every six months if you have documentation saying you've been consistently welding using the same method you tested under. If you cannot renew your license at any point, it expires. -

QuestionHow old do you have to be to become a welder?

Community AnswerMost companies will require you to be 18 because of safety hazards. But if you know someone who can teach you, or if your high school has a vocational program with a nearby college, you can learn that way.

Community AnswerMost companies will require you to be 18 because of safety hazards. But if you know someone who can teach you, or if your high school has a vocational program with a nearby college, you can learn that way. -

QuestionHow can I decide if I want to be a welder or not?

Community AnswerTry it out before you buy the equipment yourself. Watch videos online, take a class at a community college or ask a local welder for advice or an internship.

Community AnswerTry it out before you buy the equipment yourself. Watch videos online, take a class at a community college or ask a local welder for advice or an internship.

Warnings

- Welding involves working with complex machinery and tools that apply extreme heat, emit glaring light and produce potentially noxious fumes. Depending upon the industry, discipline and method of welding, the tools used to complete the job can be hazardous if not handled properly using the appropriate protective gear.⧼thumbs_response⧽

References

- ↑ http://www.arc-zone.com/blog/joewelder/2013/08/14/tips-for-selecting-a-welding-school/

- ↑ http://www.popularmechanics.com/home/how-to-plans/metalworking/4295636

- ↑ http://education-portal.com/articles/How_to_Become_a_Welding_Engineer_Education_and_Career_Roadmap.html

- ↑ http://www.aws.org/certification/

- ↑ http://www.aws.org/certification/CWEng/

- ↑ http://www.thomasnet.com/articles/custom-manufacturing-fabricating/become-welder

About This Article

If you're interested in becoming a welder, gaining some hands-on experience in an introductory college or high school course can be a good way to see if it would be a good fit for you. Work on learning the essential skills like striking an arc, tacking, and controlling your puddles. Eventually, you can look for a welding training program at a community college or through the American Welding Society. To learn about the different types of welding and what training you’ll need to find a job, read on!