wikiHow is a “wiki,” similar to Wikipedia, which means that many of our articles are co-written by multiple authors. To create this article, 23 people, some anonymous, worked to edit and improve it over time.

wikiHow marks an article as reader-approved once it receives enough positive feedback. In this case, 82% of readers who voted found the article helpful, earning it our reader-approved status.

This article has been viewed 178,433 times.

Learn more...

The job of a blacksmith involves heating metal with fire to forge, make repairs and create welds. Approximately two-thirds of blacksmiths work in manufacturing, but if you are more artistically-inclined, you can use your skills to creating decorative railings and gates, furniture and sculptures from metal. Becoming a blacksmith requires physical strength but also obtaining the proper training and developing the necessary skills.

Steps

Starting to Become a Blacksmith

-

1Read books about the profession and art of blacksmithing. Blacksmithing is a skill that requires a good deal knowledge to be able to perform, even to get started, and reading about it is the quickest and easiest way to start. Some books to start with include: The (new) Edge of the Anvil by Jack Andrews and The Art of Blacksmithing by Alex Bealer.[1]

-

2Take classes. Attend a community college or vocational school that specializes in blacksmithing to learn basic blacksmithing skills. Start by locating community colleges and vocational schools near you. Then take a look at what kind of classes they have that deal with metalworking.[2]

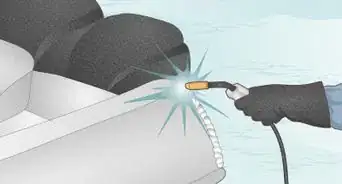

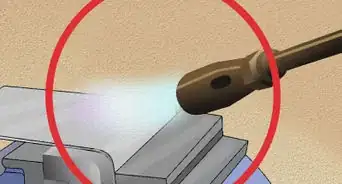

- Begin with a class that teaches oxy-acetylene (gas) welding to learn how to light the torch, safely handle hot metal, handle the tanks and what safety equipment to use while welding.

- Try to find classes that will teach you how to control heat in the forge, whether it is coal or gas fired.

- Become familiar with the blacksmithing tools, such as an anvil, hammer, tongs and punch. If you can't find any classes near you that deal with blacksmithing tools, look for online classes, and purchase your own equipment. Experiment with using these tools.

- In these classes you'll learn essential skills such as drawing out, brazing, cutting, riveting and upsetting.

Advertisement -

3Take more advanced metal work classes. Learn more modern metal-working skills that are needed to become a well-rounded blacksmith. Do this by completing the beginner metalworking classes offered either at your local community college, a vocational school, or online, and then move on to whatever intermediate and advanced classes are offered.[3]

- Learn about plasma cutting, such as the distance the electrode needs to be from the metal, the angle at which the electrode should be held and what amperage should be used to cut various thicknesses of metal.

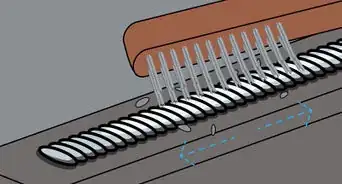

- Become skilled as a MIG (metal inert gas) and TIG (tungsten inert gas) welder. MIG welding requires a spool that is continuously fed and is useful for long pieces of metal. TIG welding requires a rod and is effective for welding aluminum.

- Arc Welding might not be a part of classical blacksmithing, but being well-rounded in your metal working skills is important if you want to make it a career.

-

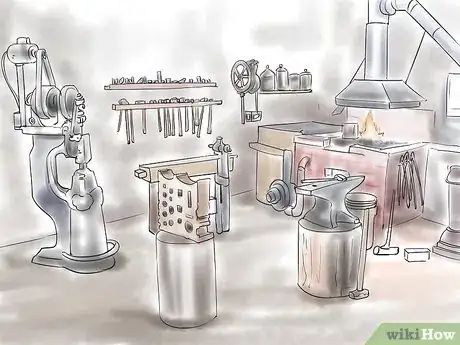

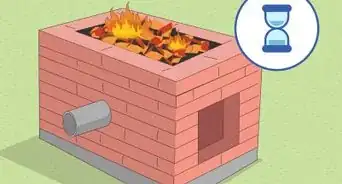

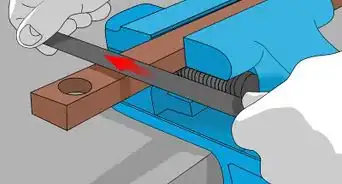

4Start building your own blacksmithing setup. Whether you're looking to become a hobbyist or you want to eventually make blacksmithing a career, you're going to eventually need your own equipment. To get starting practicing blacksmithing on your own, you'll need, at minimum, the following equipment: [4]

- A forge: A forge allows you to heat your metal so that it can be manipulated. You can either make your own forge or buy one online.

- Tongs, clamps, and a vice: These allow you to hold your heated metal so that it can be worked with securely and safely.

- An Anvil: This is what you'll rest your metal on when you hit into shape.

- Hammers: These are what you'll hit the metal with. They come in manner shapes in sizes, all for different purposes.

- Safety equipment. Strong leather gloves, a heavy-duty apron, and a blacksmith mask will keep you safe when dealing with dangerously hot temperatures.

- Most of this equipment can be bought online. Just do some research first before making a purchase.

Training at Blacksmithing

-

1Join ABANA (Artists Blacksmiths Association of North America). Look for an ABANA Chapter near you, then look into how to join that particular Chapter. Then consider attending ABANA meetings. You'll learn more about blacksmithing, meet other blacksmiths, and get a chance to become a part of the blacksmithing community. ABANA has both professional blacksmiths and hobbyists.[5]

-

2Join an apprenticeship program where you will be able to hone the necessary skills to become a blacksmith. Search online for blacksmithing apprenticeships and internships near you. The structure of these apprenticeships vary but generally it involves being paired with a master blacksmith for one-on-one training and experience building.

- Some blacksmithing apprenticeship programs require qualification through a demonstration of basic blacksmithing skills, but many are designed for beginners with no blacksmithing experience.

-

3Further advance your skill by joining a journeyman program. By becoming a journeyman, you will work in the shop of a professional blacksmith. Here you can learn a variety of styles and possibly work with architects to design details for new and old construction.[6]

- ABANA provides the means to join a journeyman program through their website. Here you can fill out their questionnaire and join their registry, where aspiring blacksmiths can match with professional blacksmiths looking for understudies.

- To join a journeyman program, you'll need to meet a minimum level of skill and competency with blacksmithing and metal working in general. The skills a journeyman is expected to know are listed on ABANA's website, and include things such as drawing out, heat treating, and basic metallurgy.

Finding a Blacksmith Profession

-

1Find work in any metal working trade. Look into jobs that require less experience to build your experience and knowledge of the metal working business. As with most careers, starting from the bottom, gaining any experience you can, and slowly working your way up is a viable method for becoming a professional. Some ideas include being a cleaner at a local machine shop or working in a steel center warehouse.[7]

- Most of the jobs you'll be able to find as a hobbyist blacksmith won't involve any forging, but they'll be a first step into the metal working business, and give you experience that can help you land a blacksmithing job later.

-

2Establish your own blacksmith shop. If you're more the self-starter type, you might want to give starting your own small blacksmithing business a shot. Once you've got the tools and the know-how, it becomes a matter of marketing and business skills. Most blacksmiths who make their own shop focus on artistic blacksmithing. [8] Consider starting out by learning how to make custom metal art, like swords and sculptures, and start selling them through commerce websites like Etsy.

- The key to creating a successful self-start blacksmith shop is to slowly build a base of satisfied customers and make a name for yourself. There's a market out there for expertly hand-crafted functional metal art. Finding your place in that market is your goal.

-

3Find a job as a commercial blacksmith. Manufacturers of many types of machines, transportation and railings require the skills of blacksmiths. Like with many other niche industries, the key to getting your foot in the door is networking. Once you have the skills, the next step is meeting the right people, which goes back to joining blacksmith associations and affiliates and getting involved.[9]

- One way into a commercial blacksmithing job is to start working for the professional blacksmith you learned from in a journeyman or apprenticeship program.

-

4Become a demonstrator of blacksmith techniques at living history museums or fairs. Apply for these positions directly or through blacksmithing guilds or chapters. These jobs may be hard to come by but if you're in the right place at the right time you can find them. These jobs involve demonstrating the art of blacksmithing to the public.

Community Q&A

-

QuestionCan you make weaponry in a forge?

Community AnswerYes, if you have the right equipment and skills.

Community AnswerYes, if you have the right equipment and skills. -

QuestionWhat do I need to make a blacksmith's shop?

Community AnswerAn anvil, and a forge. You will need some tools here and there, like a hammer. Not to mention fuel for your forge, as well as a flue. You will need a place to put everything that is out of the way of others (since blacksmithing isn't particularly quiet). Then you'll need safety gear, a leather apron, boots, long sleeved shirt, eye protection, and gloves. Generally blacksmiths put anvils on top of a wooden log, in order to quiet the noise it produces. (As well as provide a stand for it) You will need some place to set the metal down when it is red hot and in need of cooling as well as a quenching trough (or bucket) for the metal you want cooled quickly.

Community AnswerAn anvil, and a forge. You will need some tools here and there, like a hammer. Not to mention fuel for your forge, as well as a flue. You will need a place to put everything that is out of the way of others (since blacksmithing isn't particularly quiet). Then you'll need safety gear, a leather apron, boots, long sleeved shirt, eye protection, and gloves. Generally blacksmiths put anvils on top of a wooden log, in order to quiet the noise it produces. (As well as provide a stand for it) You will need some place to set the metal down when it is red hot and in need of cooling as well as a quenching trough (or bucket) for the metal you want cooled quickly. -

QuestionWhat metal can I use that is not that heavy, but very strong?

Community AnswerThe best metal to use is steel. It's affordable and durable. Steel is good for making knives, swords, axes, etc. Titanium is stronger and lighter than steel, but is expensive and hard to work with.

Community AnswerThe best metal to use is steel. It's affordable and durable. Steel is good for making knives, swords, axes, etc. Titanium is stronger and lighter than steel, but is expensive and hard to work with.

References

- ↑ http://www.anvilfire.com/FAQs/getstart/

- ↑ http://www.anvilfire.com/FAQs/getstart/

- ↑ http://www.anvilfire.com/FAQs/getstart/

- ↑ http://www.artofmanliness.com/2011/07/14/blacksmithing-primer/

- ↑ http://www.anvilfire.com/FAQs/getstart/

- ↑ http://www.theartcareerproject.com/become-blacksmith/

- ↑ http://www.anvilfire.com/FAQs/getstart/

- ↑ https://nationalcareersservice.direct.gov.uk/advice/planning/jobprofiles/Pages/blacksmith.aspx

- ↑ http://www.theartcareerproject.com/become-blacksmith/

About This Article

To become a blacksmith, learn basic skills like how to light a torch, safely handle hot metal, and control heat in a forge. You should also get familiar with blacksmithing tools such as anvils, hammers, tongs, and punches. Next, take classes to learn techniques like drawing out, brazing, riveting, and plasma cutting. Then, join an apprenticeship program to be paired with a master blacksmith for one-on-one training. Once you're trained, start looking for a job as a commercial blacksmith. For tips on creating your own blacksmithing setup, read on!