wikiHow is a “wiki,” similar to Wikipedia, which means that many of our articles are co-written by multiple authors. To create this article, 34 people, some anonymous, worked to edit and improve it over time.

wikiHow marks an article as reader-approved once it receives enough positive feedback. In this case, 91% of readers who voted found the article helpful, earning it our reader-approved status.

This article has been viewed 158,293 times.

Learn more...

If you're keen to do some basic blacksmithing, here are the basic techniques for you to try on your own. There are tips for working the steel, types of tools and some clear warnings on working with steel.

Steps

-

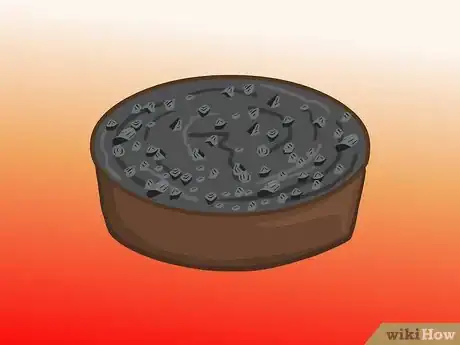

1Build a small forge. A simple one can be built by adding an airblast of any kind that is strong enough to withstand any kind of fire, but coal or charcoal (not briquets) works best.

-

2Get some steel rods or rebar. Make sure you do not use galvanized steel. Galvanized steel has a layer of zinc on it to protect it from rust and further corrosion. Zinc has a much lower melting temperature than steel, and once heated, it will turn a greenish yellow color and produce thick white smoke. This smoke is the zinc burning off, and If you inhale too much of this smoke you can potentially contract "metal fume fever". If you do decide to use galvanized steel, make sure to wear a respirator, and do it in a well ventilated area. A way to check if it is galvanized or not is to check:

- 1. Is it shiny? If it has a glossy sheen to it it is likely covered in the toxic coating.

- 2. Does it say so on packaging or labels?

- If you are unsure, make sure you consult your supplier before possibly hurting yourself. Make sure they are about 3 feet (0.9 m) long, so you can hold onto a cool part of the steel while forging on the ends or other parts of the bar.

Advertisement -

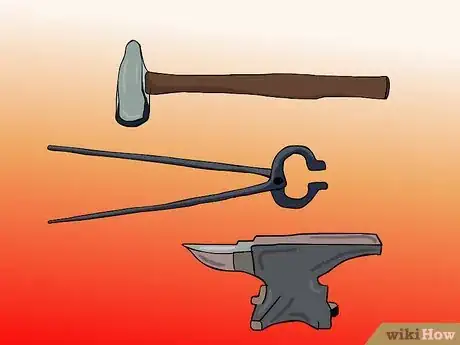

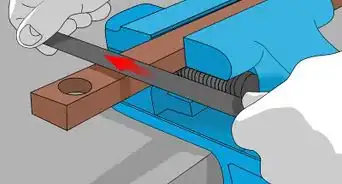

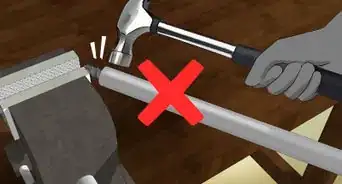

3Assemble your tools. A hammer can be easily found at yard sales, antique stores, or just a plain hammer from the hardware store. But make sure it is not a carpenters hammer (one with the two prongs) as the head is too small to be of much use and the prongs will not help with anything. As long as the face is smooth and doesn't have any grooves, it should be a decent hammer for beginners. If your hammer has grooves, you'll need to sand them out. One hammer is all that is needed for now, and a nice pair of vice-grips or will work as tongs.

-

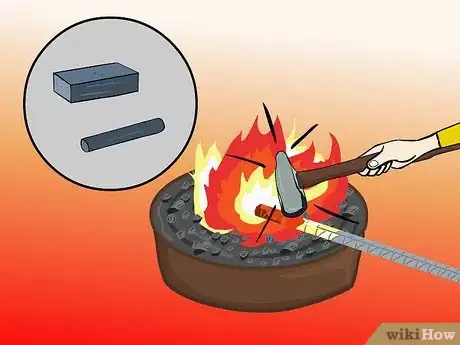

4Build your fire. Remember to be safe; it is a fire! Do it outside in a clearing, free of brush and other things that can easily catch fire. Have a garden hose, buckets of water, or a fire extinguisher at the ready. Build a nice pile in the center of the forge, lining around it with rocks. If using coal, you may want to "coke" it before heating your steel. This entails slowly heating the coal for a while until it looks like giant pieces of popcorn. This holds heat much better and burns for longer. Or use a 1 foot (0.3 m) section of a 55 gallon (208.2 L) drum.

-

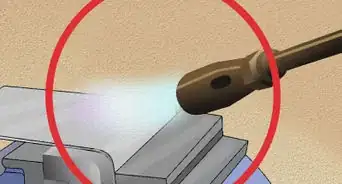

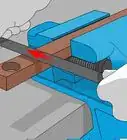

5Insert your steel into the heart of your fire and add the air blast. Wait patiently, checking the color of the steel by quickly sliding it out and putting it back in. If you wait too long, you will loose heat. The steel should be placed near the air blast, but not so close so that the air is blowing directly onto the piece.

-

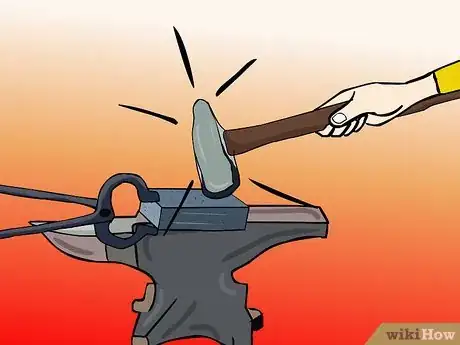

6After you have assembled your tools, and lit a nice hot fire, get hammering! When rebar and scrap metal has reached the optimal working temperature, it will be colored between dark orange and bright yellow (not white).

-

7Practice definitely makes perfect. Some beginner techniques to try include turning a square bar into round, round bar into square, tapering (which means making the end pointy - the nicer and more slender the taper the better), flattening (the more even thickness the better), and just general scrolls (curls) and bends.

-

8Practice some more, be careful, think safety, and overall have fun!

Community Q&A

-

QuestionHow do I do blacksmithing safely?

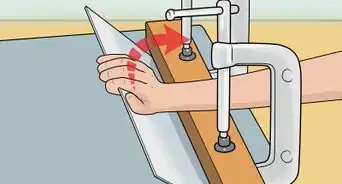

Community AnswerAt a minimum, I would recommend ear protection, safety glasses, leather apron, heavy duty welding gloves, and fire-resistant natural fiber clothing - cotton is good. Wear long sleeves, blue jeans, and work boots. Synthetic fibers like nylon can catch fire and melt to your skin. Have a firm grip on the red-hot iron you're working so it doesn't fly back and hit you when you strike it. Have a bucket of water and/or fire extinguisher handy. Don't do it next to gasoline, paint thinner, or other solvents. If you use power tools, read and follow all the safety instructions.

Community AnswerAt a minimum, I would recommend ear protection, safety glasses, leather apron, heavy duty welding gloves, and fire-resistant natural fiber clothing - cotton is good. Wear long sleeves, blue jeans, and work boots. Synthetic fibers like nylon can catch fire and melt to your skin. Have a firm grip on the red-hot iron you're working so it doesn't fly back and hit you when you strike it. Have a bucket of water and/or fire extinguisher handy. Don't do it next to gasoline, paint thinner, or other solvents. If you use power tools, read and follow all the safety instructions. -

QuestionIs it safe to bend the metal while it's still hot? How would I do it?

Community AnswerYes, it is safe. Use 2 pairs of tongs or pliers to bend it to the desired angle.

Community AnswerYes, it is safe. Use 2 pairs of tongs or pliers to bend it to the desired angle. -

QuestionDo I need any chemicals or oils?

Community AnswerIt really depends on what you’re doing. Many types of oils can be used for quenching (hardening tool steel), such as vegetable or motor oil. Linseed oil is a good thing to apply onto finished products due to its anti-rust properties. As for chemicals, you may need a flux (such as borax) for forge welding or an etching acid if you have made something out of pattern-welded or Damascus steel. Generally, blacksmiths, with the exception of bladesmiths, do not often use oils or chemicals.

Community AnswerIt really depends on what you’re doing. Many types of oils can be used for quenching (hardening tool steel), such as vegetable or motor oil. Linseed oil is a good thing to apply onto finished products due to its anti-rust properties. As for chemicals, you may need a flux (such as borax) for forge welding or an etching acid if you have made something out of pattern-welded or Damascus steel. Generally, blacksmiths, with the exception of bladesmiths, do not often use oils or chemicals.

Warnings

- Never use any metal that can enclose air. It can expand, sometimes causing it to explode, which can cause serious burns, injuries, and death.⧼thumbs_response⧽

- When cooling iron or steel pipe in a water bucket, point the opening away from yourself to avoid being burned by hot steam.⧼thumbs_response⧽

- Cool all metal down in water when you are done forging for the day.⧼thumbs_response⧽

- Fire is dangerous, and so is hot metal, don't leave either unattended.⧼thumbs_response⧽

- The most dangerous heat is what's called a black heat. It is not red hot but it can still be above 400 °F (204 °C), hot enough to seriously burn you.⧼thumbs_response⧽

- Be careful!!⧼thumbs_response⧽

- Hot steel looks the same as cold steel sometimes, be careful where you grab⧼thumbs_response⧽

- Never heat galvanized, zinc, or nickel plated steel. Heavy metals when heated turn into a poisonous gas containing extremely dangerous heavy metals that if inhaled can cause sickness or even death!⧼thumbs_response⧽

- Do not use galvanized steel. It gives off very poisonous fumes when heated up. These fumes can kill you. Under no circumstances use galvanized steel, sheet metal, nails, rods - do not use galvanized anything!⧼thumbs_response⧽

- Do not use an ASO! Most ASOs are cast iron and you will get pretty much nowhere with one.⧼thumbs_response⧽

Things You'll Need

- Tools - anvil, pliers or tongs (Start with 2-foot long pliers), a hammer or two(preferably cross-pen and/or ball-pen),

- Some steel to work with, not galvanized (see warning above)

- Eye protection

- Welders apron

- A wire brush

- (Optional) Beeswax (This gives the metal a black-ish sheen)