This article was co-authored by wikiHow staff writer, Hannah Madden. Hannah Madden is a writer, editor, and artist currently living in Portland, Oregon. In 2018, she graduated from Portland State University with a B.S. in Environmental Studies. Hannah enjoys writing articles about conservation, sustainability, and eco-friendly products. When she isn’t writing, you can find Hannah working on hand embroidery projects and listening to music.

There are 8 references cited in this article, which can be found at the bottom of the page.

This article has been viewed 104,823 times.

Learn more...

Do you dream of living in a beautiful log home, surrounded by nature? Building a log house can help you achieve that dream while still keeping some of the amenities of a traditional home. You can hire a professional to do it for you, or you can take a DIY approach for a more hands-on experience. Knowing your way around some basic concepts can make the process go quickly and smoothly, and if all goes well, you could be enjoying your log house in about 1 year!

Steps

Planning Your Log House

-

1Decide on a log house or a log cabin. While the 2 terms are very similar, the outcomes are slightly different. A log cabin is a smaller, less modern version of a log house that’s usually secluded out in the woods somewhere. A log house is any structure made of wooden logs, with amenities just like any other home would have.[1]

- In other words: log cabins are usually found in the woods, while log houses can be put anywhere.

- You might choose to build a log house as your vacation home, your beach house, or as your main living area.

-

2Hire a builder if you want your log house done quickly. You have 2 options for building your log house: a professional builder, which will save you time but might cost more, or a DIY option, which can cut costs but might stretch your timeline. You can look around at professionals in your area to get a sense of how much it might cost to get your log home done by a builder, then make a decision based on that.[2]

- Usually, log houses cost about $20,000 in total. This price can fluctuate based on size, location, and timeline.

- The length of time varies from home to home, but log houses usually take around 9 months to complete.[3]

Advertisement -

3Go for a kit to get all your materials at once. Believe it or not, there are actually log house kits that you can purchase for an all-inclusive, one-time cost. The kits come with everything you’ll need to complete your house, including lumber, plumbing, electrical, and insulation. The main drawback of a log house kit is that it’s less customizable, so you may end up with a home that looks the same as someone else’s.[4]

- Log house kits range in price, but they’re usually between $20,000 and $35,000.

- If you purchase a kit and it doesn’t work for you, contact the manufacturer to talk about a replacement or a refund.

- Some kits give you the option of looking around for your own local materials to find the best price.

- If you don’t want to use a kit, you’ll have to work with an architect or an engineer to create blueprints for your log home.

-

4Plan for challenges along the way. Just like a normal home, log houses do come with some difficulties that you might have to account for. Rot, moisture from the ground, UV rays, wind, and pests can all wreak havoc on your log house during and after the building process.[5]

- If you’re getting your log house built by a professional, you can discuss where the best area is to mitigate most of these problems. Otherwise, try to choose a location that has mostly dry soil and large trees for shade.

- Tall foundations can help keep bugs and insects out of your home.

-

5Get a building permit. Submit your plans to the local permit office for approval before you start any work on your log house. You will also need to find out what building codes you log home needs to adhere to, since these can vary from state to state. If you’re working with a professional, they can point you in the right direction; otherwise, ask your local permit office.[6]

- Building codes usually ensure that your house is up to safety standards so that you and your family can live in it without doing any harm to yourself or the environment around you.

Starting Your Log House

-

1Set your budget. Log homes can easily cost upwards of $30,000, and it’s best to be prepared for the bill. Set aside your money and try to stick to your budget as much as you can to avoid overspending and going into debt.[7]

- You may be able to get a loan from your bank to cover the costs up front.

-

2Use whole, round, non-milled logs. Like you may have guessed, the logs you use for your home are super important. When you’re purchasing your materials, go for whole, round, non-milled logs to protect the integrity of your home over time.[8]

- You can purchase these from most lumber yards or specialized lumber yards that sell materials for log homes and cabins.

- Stay away from flat logs, or logs that interlock into each other. These can cause rot and lead to damage over time, so it’s best to go for completely rounded logs.

-

3Build in at least 7 ft (2.1 m) of overhang. The overhang, or the part of the roof that hangs out over the walls, protects your logs from wind, rain, and rot. At the bare minimum, you should factor in 7 ft (2.1 m) of overhang, if not more, to protect your logs and keep them around for a long time.[9]

- If you’re working with an experienced builder, they’ll probably know this already, but it’s always good to keep in mind.

-

4Get enough insulation to cover the floor and the ceiling. Insulation is something that many log homes don’t have, but not using insulation can cause the wood to overheat or freeze. At a minimum, try to use enough insulation to cover the floor and the ceiling to keep your house cool in the summer and warm in the winter.[10]

- You can also look into installing drywall in the interior for more insulation, but it’s not totally necessary.

-

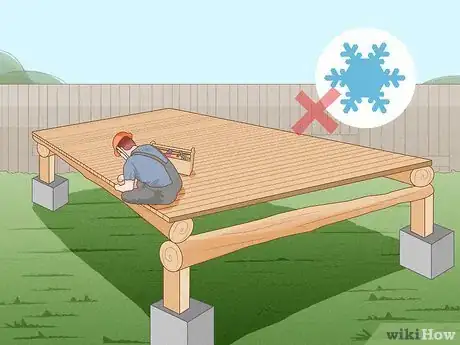

5Avoid starting your log home in the winter. The winter months bring freezing temperatures and bad weather, which can lead to rot or splitting. Try to do most of your construction during the warmer months when the weather is mild so you can start out with dry, clean materials.[11]

- Weather can cause delays in construction, so it’s always good to set aside some time in your timeline for unforeseen circumstances.

Constructing the Log House

-

1Source and prepare your logs. The logs you use are super important, and you need to dry them out really well before you start. If you’re getting your logs cut from a lumber yard, give them at least 2 months to finish all of them before you start building. If you’re cutting your logs yourself, dry them out for at least 6 months before you start building your home.[12]

- Using wet logs can cause shrinkage and lead to warping later on. It’s always better to take the time now than regret it later on.

-

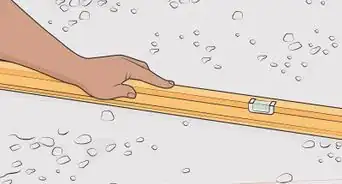

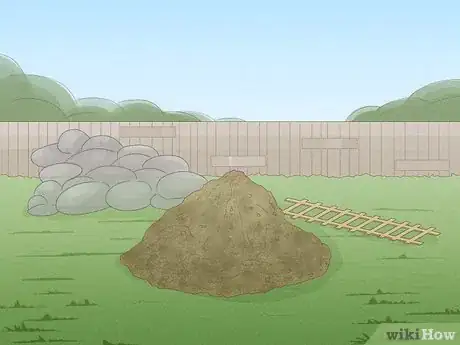

2Clear and level your land. You’ll need a perfectly level foundation to start your log house on, so get to digging! If there’s vegetation and rocks in the way, this process could take up to a week. If you have to level out a hillside or a slope, it could take much longer. You can use shovels or an excavator for large plots.[13]

- If your ground isn’t level, your house won’t be level.

-

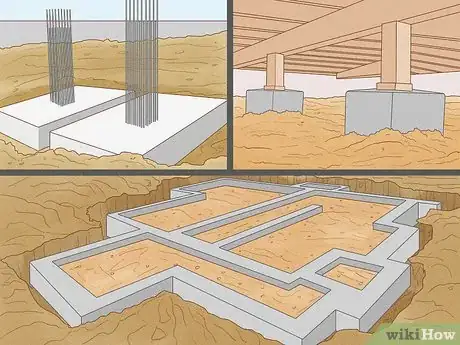

3Pour the foundation. The foundation must be below the frost line, which is usually about 3 to 4 inches (7.6 to 10.2 cm) in the ground. There are a few different foundation types you can use, and you can choose them based on what your budget is and how long you have. Most foundations take about 3 weeks to install from start to finish, so allow a good chunk of time for this process. The foundation types include:[14]

- Strip foundation: most expensive and most time-consuming, but it can help level out uneven ground.

- Raft foundation: less expensive and time-consuming, and it can help evenly distribute the weight of the house.

- Concrete pier foundation: the easiest and least expensive, but it does take some excavation work before you can pour it.

-

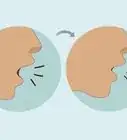

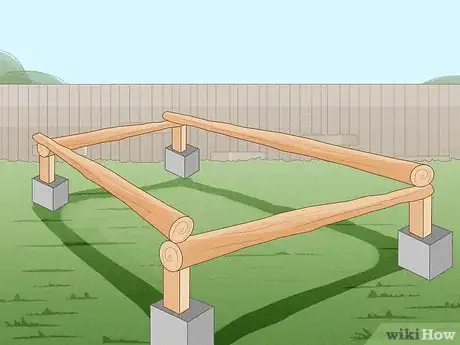

4Lay the first 4 logs on the foundation. Now comes the actual construction of your log house! To fit the logs together, use a chainsaw to carve out a notch into 2 of the logs. Then, lay down the 2 notched logs on the foundation with the 2 un-notched logs on top in a square shape. Now you’ve got your first layer of logs of your log house.[15]

- Notching your own logs can take a long time, so try to buy them pre-notched, if you can.

- Making a notch with a chainsaw usually takes around 5 minutes. While this sounds quick, when you’re doing it for each log, it can be a huge time-sink.

-

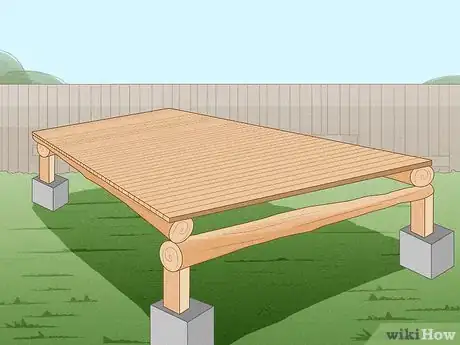

5Install the floor. Attach floor joists about 14 in (36 cm) apart across the 4 initial logs that you installed previously, using notches to attach each one. Then, lay your flooring planks across the joists to keep them in place and make your floor. The floors are usually pretty quick to install, since you don’t need much hardware for them.[16]

- Try to use 2 by 7 inches (5.1 by 17.8 cm) logs for the joists so your floor is level and secure.

- If you’re adding insulation to the floor, put it on top of the joists but underneath the flooring planks.

-

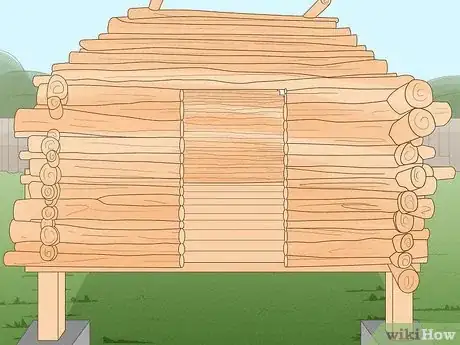

6Stack the logs to create walls. Now you can take the rest of your logs and stack them one on top of the other to create the 4 walls of your home. If your logs aren’t notched already, you’ll have to add notches to each one before you place them. If your logs are from a kit or a lumber yard, this part will go quickly since you won’t have to notch them on your own.[17]

- Remember to always look at the plans you created to make sure you’re using the right amount of logs.

- The width and height of your walls depends on the overall size of your home, so it’s different for every log house.

-

7Carve out doors and windows. Mark out where you’d like to install doors and windows in your home, then use a chainsaw to cut holes in the walls to make room for them. Then, you can install your windows by fitting them into place and add a door by using hinges. This part doesn’t take very long, but make sure your measurements are precise![18]

- It’s better to cut too little at first than too much.

-

8Frame and attach the roof. You’re almost done! Now you have to decide on what kind of roof you’d like (thatched, shingles, metal, and felt are all popular options) before adding a frame. Once you have your roof frame, you can add notches into the roofing joists and attach the rest of your roof.[19]

- The length of time for this process depends on your materials, but it usually takes anywhere from 1 day to 1 week.

-

9Clean and stain your logs. It’s time to protect the home you worked so hard for. Use a rag and water to clean off the exterior of your home, then paint on a wood stain to protect it from UV rays. You can choose any wood stain that you’d like, as long as you reapply it every 18 to 24 months.[20]

- Not staining your wood can lead to damage and rot, so it’s a really important step.

- If staining at the end is too difficult, you can also stain each log as you construct your house.

-

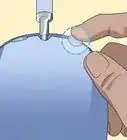

10Seal your log house with caulk. To keep out moisture, grab a caulking gun and use it to apply caulk along the length of your joists. You should fill any crack or split that’s over 2 cm (0.79 in) wide to avoid problems in the future. Once the caulk dries, you can sand it down and clean it off for a nice finish.[21]

- You might want to keep your caulk around for the future just in case you notice any cracks later on.

Community Q&A

-

QuestionHow much land must I have to build a log cabin?

Community AnswerThere is no set amount of land you need to build a log house, you just need somewhere big enough for your plans.

Community AnswerThere is no set amount of land you need to build a log house, you just need somewhere big enough for your plans. -

QuestionCan I make the frame out of PVC pipe instead?

Community AnswerYou can, but the rest of the house would have to be made of PVC too. PVC alone is not strong enough to support the weight of many logs.

Community AnswerYou can, but the rest of the house would have to be made of PVC too. PVC alone is not strong enough to support the weight of many logs.

Warnings

- Log houses require a lot of maintenance, and they can rot if they aren’t cared for properly.⧼thumbs_response⧽

Things You’ll Need

- Round, non-milled logs

- Chainsaw

- Wood stain

- Caulk

References

- ↑ https://www.newhomesource.com/learn/log-cabin-homes/

- ↑ https://www.logcabinhub.com/costs-to-build-a-log-cabin/

- ↑ https://www.logcabinhub.com/how-long-does-it-take-to-build-a-log-home/

- ↑ https://www.bobvila.com/slideshow/8-low-cost-kits-for-a-21st-century-log-cabin-48639

- ↑ https://www.loghome.com/articles/article/deter-your-log-homes-natural-enemies1

- ↑ https://www.logcabinhub.com/costs-to-build-a-log-cabin/

- ↑ https://www.logcabinhub.com/costs-to-build-a-log-cabin/

- ↑ https://www.lhba.com/3-how-to-build-a-log-cabin

- ↑ https://www.lhba.com/3-how-to-build-a-log-cabin

- ↑ https://www.logcabinhub.com/costs-to-build-a-log-cabin/

- ↑ https://homesteading.com/build-log-cabin-by-hand/

- ↑ https://www.logcabinhub.com/how-long-does-it-take-to-build-a-log-home/

- ↑ https://www.logcabinhub.com/how-long-does-it-take-to-build-a-log-home/

- ↑ https://homesteading.com/build-log-cabin-by-hand/

- ↑ https://www.logcabinhub.com/how-to-build-a-log-cabin/

- ↑ https://www.logcabinhub.com/how-to-build-a-log-cabin/

- ↑ https://homesteading.com/build-log-cabin-by-hand/

- ↑ https://www.logcabinhub.com/how-to-build-a-log-cabin/

- ↑ https://www.logcabinhub.com/how-long-does-it-take-to-build-a-log-home/

- ↑ https://www.logcabinhub.com/how-to-build-a-log-cabin/

- ↑ https://www.logcabinhub.com/how-to-build-a-log-cabin/

-Step-19-Version-2.webp)