wikiHow is a “wiki,” similar to Wikipedia, which means that many of our articles are co-written by multiple authors. To create this article, 12 people, some anonymous, worked to edit and improve it over time.

wikiHow marks an article as reader-approved once it receives enough positive feedback. In this case, 90% of readers who voted found the article helpful, earning it our reader-approved status.

This article has been viewed 257,737 times.

Learn more...

Knowing Takt time helps you to estimate your service delivery process and process/software outcome. It can help you achieve a consistent, continuous flow of production, eliminate the waste of overproduction by producing to actual customer demands, and develop standardized work instructions (thus promoting quality and efficiency). More importantly, Takt time enables you to set real time targets for production that show the staff exactly where to focus their output efforts. To calculate Takt time, simply divide your available time by the rate of customer demand.

Steps

-

1Understand what Takt time is. Takt time is the pace of production (E.g in Manufacturing one piece every minute) that aligns production with customer demand.

- In simple terms, it is how fast you need to manufacture products in order to fill your customer demand.

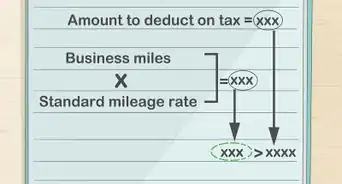

- Takt time calculation=Available time / customer demand. For example, if a customer requires 100 bulbs a day, the Takt time is 8 hrs /100.

- 8 hrs is the working time in your 9 hours working day (so you need to exclude your breaks, meetings etc) to mention the available time(numerator).

- This means a bulb to be completed every 4.8 minutes.

-

2Calculate your demand. How much time does your end-user or customer typically want every day/week/month?Advertisement

-

3Calculate your available time. Exclude your breaks, meeting times, and other unavailable time.

-

4Calculate your Takt time. This is available time/demand. Divide your available time by the demand time.

-

5Compare your cycle time against Takt time using any chart. It is recommended to plot a Bar chart.

-

6Draw a value stream mapping and there you can provide the Takt time at each activity step.

Community Q&A

-

QuestionWhat does calculating Takt time do?

Community AnswerKnowing takt time gives you a better understanding of your service delivery process, thereby giving you the ability to help maximize efficiency and minimize waste.

Community AnswerKnowing takt time gives you a better understanding of your service delivery process, thereby giving you the ability to help maximize efficiency and minimize waste. -

QuestionHow close should the cycle time be to the takt time?

Community AnswerFor optimum operation, you should strive to have the two be the same or very close to the same.

Community AnswerFor optimum operation, you should strive to have the two be the same or very close to the same. -

QuestionHow do you calculate the available time?

Community AnswerAvailable time = Planned production time - Down time and Stop time. Planned production time = Shift length - Breaks. Stop time = break time, meeting time, and/or changeover time.

Community AnswerAvailable time = Planned production time - Down time and Stop time. Planned production time = Shift length - Breaks. Stop time = break time, meeting time, and/or changeover time.