This article was co-authored by wikiHow Staff. Our trained team of editors and researchers validate articles for accuracy and comprehensiveness. wikiHow's Content Management Team carefully monitors the work from our editorial staff to ensure that each article is backed by trusted research and meets our high quality standards.

There are 13 references cited in this article, which can be found at the bottom of the page.

This article has been viewed 54,677 times.

Learn more...

PEX tubing is a great alternative to copper tubing because it is flexible and requires fewer connections. You can easily cut through it using a special PEX cutter, available at hardware stores or online. Measure the tubing carefully before making any cuts, then use your cutting tool to make a clean cut through the PEX tubing.

Steps

Choosing Tools

-

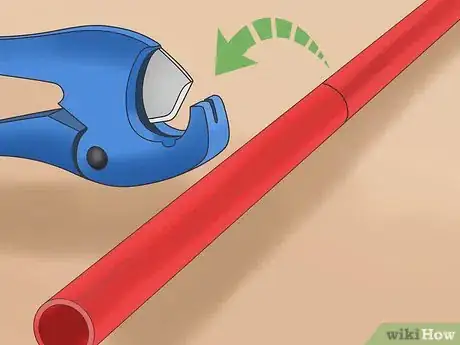

1Be sure to use a specialized PEX cutter tool. Only specially-designed PEX cutter tools should be used to cut PEX tubing. Common household tools such as saws may be dangerous to use given the density of pex tubing. Visit your local hardware store or look online for a PEX cutter.[1]

-

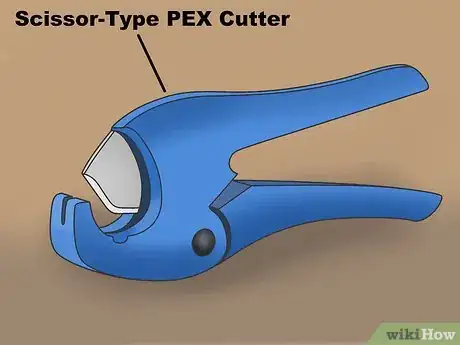

2Purchase a basic, scissor-style PEX cutter. A simple PEX cutter will be adequate to cut through PEX tubing but it may require some muscle. This model of PEX cutter is the most economical choice. Look for a model with easy-to-grip handles that will make it more comfortable to use.[2]

- Basic PEX cutters usually range from approximately $10 to $20.

Advertisement -

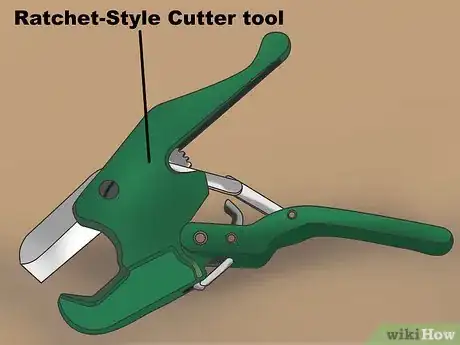

3Purchase a ratchet-style cutter tool for an easier cut. Ratchet style PEX cutters are more expensive than regular, scissor style cutters but are easier to use. With a stronger blade and firmer grip, this tool will usually cut through PEX tubing in one squeeze, Compare models and prices to get the best cutter for your money.[3]

- Ratchet-style PVC cutters can cost anywhere from $20 to $100.

-

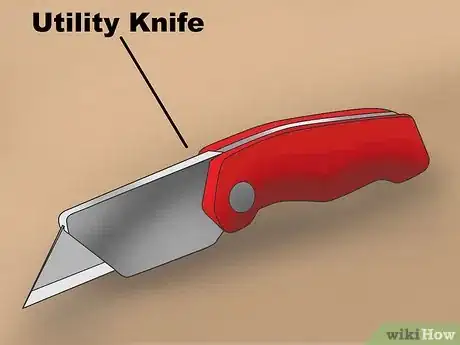

4Use a utility knife to make minor cuts in a pinch. While a utility knife is not the ideal choice for cutting PEX tubing, it may be used in an emergency. Hold the knife perpendicular to the piping and insert the tip of the blade into the middle. Pull the blade downwards to cut through the piping halfway. Pull the knife around to the other, uncut side of the piping and slowly cut though the rest of the piping.[4]

- Cut slowly to ensure a clean line.

-

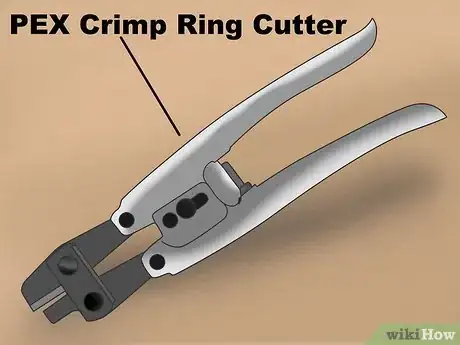

5Get a PEX crimp ring cutter for removing crimp rings. If you are cutting PEX tubing for the purpose of removing a crimp ring, you will need a special PEX crimp ring cutter tool. This tool will squeeze between the piping and the ring, allowing you to make a clean cut. Opt for cutters with easy-to-grip handles and a strong blade.

-

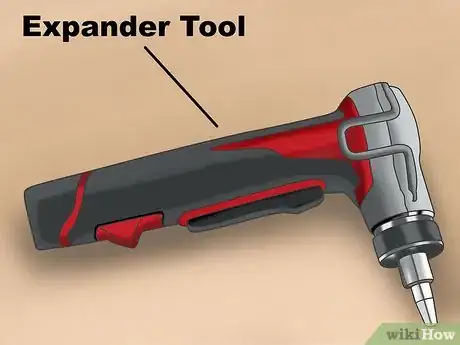

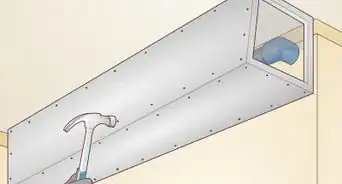

6Buy an expander tool to stretch PEX piping. If you want to attach PEX piping to a valve, fitting, or manifold, you will have to stretch the tip of it first. If you are only making a few attachments, purchase a hand-operated expander tool online or in a hardware store. You can also buy an automatic expander tool if you have to make a large number of these connections.

Measuring and Making the Cut

-

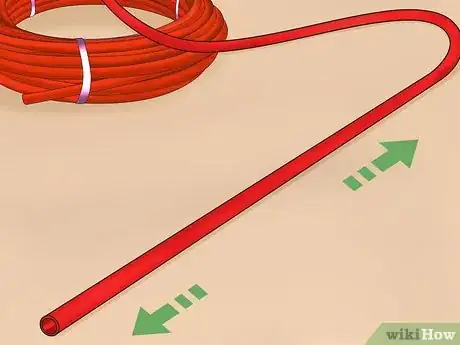

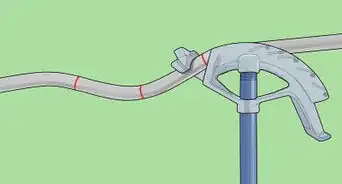

1Straighten out the PEX tubing as much as possible. To ensure that you measure PEX tubing properly and cut it evenly, straighten out the tubing. Fold the tubing upward in the opposite direction that it is curling. Lay it down on a flat surface to make sure it is as straight as possible.[5]

-

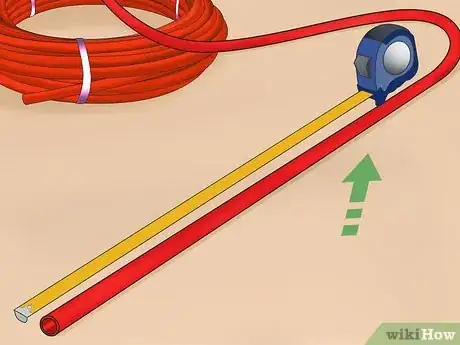

2Measure your piping and add about 1 inch (2.5 cm). PEX piping should never be stretched tightly between fittings. Use a measuring tape to find out exactly how much piping you need, then add about 1 inch (2.5 cm). This will leave room for the flexible piping to expand and contract.[6]

-

3Mark the cutting line clearly with a pen or fine point marker. Having a clearly marked cutting line will make the process of cutting your PEX tubing simple and help you avoid mistakes. After measuring your piping, draw a line to mark exactly where you want to cut. Use a pen or fine point marker to ensure that the line will not fade or wipe off before you make the cut.

-

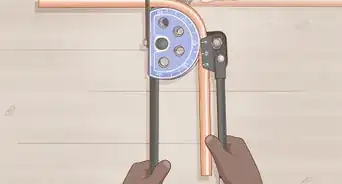

4Insert the part of the PEX tubing you want to cut into the mouth of the tool. Place the PEX tubing into the mouth of the tool where you want it cut. Position the exact line you wish to cut through directly under the blade. Hold it firmly in place.[7]

-

5Squeeze the cutter tool firmly for a clean cut. Grip the handles of your cutter tool firmly. Squeeze them together in a strong, smooth motion so that the mouth closes on the tubing, pushing the blade down onto it. Keep squeezing until the blade goes completely though the tubing, or until you have squeezed the handles as far as they will go.[8]

-

6Keep squeezing and twist the cutter downwards to finish the cut. If you are using a smaller PEX cutter, the first squeeze might not make a clean cut. If this is the case, stop and allow the mouth of the tool to reopen. Squeeze the cutter again and twist it downwards slightly to finish the cut.[9]

Cutting PEX Tubing to Remove Crimp Rings

-

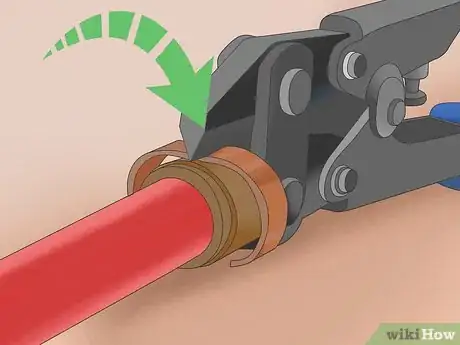

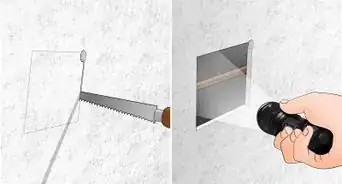

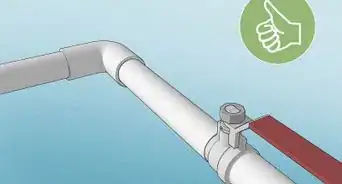

1Clamp a pair of pliers beside the fitting. Fittings are secured with crimp rings, so it can be difficult to remove the latter without damaging the former. Start by gripping 1 side of the fitting with the open mouth of a pair of pliers. Clamp them down on the PEX piping as closely to the fitting as possible.[10]

- The pliers will allow you to cut closely to the fitting but prevent you from cutting down onto it.

-

2Position your PEX cutter on the opposite side of the fitting and cut. With your free hand, place the open mouth of your PEX cutter over the tubing, on the other side of the fitting. The tool should be right next to the pliers, leaving just enough space to accommodate the fitting. Squeeze the tool to cut through the PEX piping. [11]

-

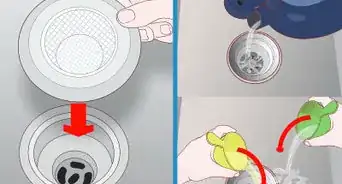

3Use a PEX crimp ring cutter to remove the ring. Keep the PEX tubing in place with the pliers. Put down the PEX cutter and pick up a PEX crimp ring cutter with that hand. Place the fat part of the mouth of the cutter on top of the crimp ring, leaving the skinny part underneath it. Slowly squeeze the handles until the blade at the top cuts though the ring.[12]

Installing PEX Tubing

-

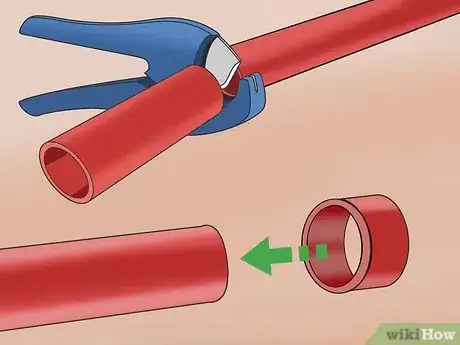

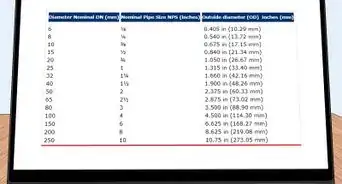

1Cut the piping and place a compression ring on the end. Use a PEX cutter or PVC cutter to cut the piping to the length you need. Slide a compression ring onto the end of the pipe. The ring will help secure your PEX piping to a valve, fitting, or manifold.[13]

- Compression fittings are available in different sizes. Choose the size that corresponds to the size of your PEX tubing.

-

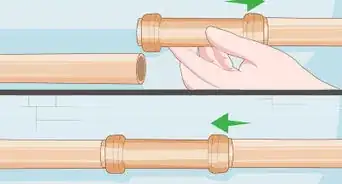

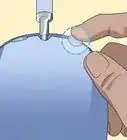

2Stretch the piping with an expander tool. Insert the head of your expander tool into the end of the cut pipe. Squeeze the tool to open its tip, which will enlarge the pipe and the ring around it. Squeeze several times until the pipe is stretched enough to fit around the end of the valve, fitting, or manifold it is going onto.[14]

- Remove the tool once the pipe is stretched enough.

-

3Attach the PEX pipe to the valve, fitting, or manifold. Place the stretched end of the PEX piping over the valve, fitting, or manifold you are connecting it to. Position it so there is around .25 inches (0.64 cm) of overlap. The PEX pipe will slowly shrink back to its original size and clamp down on the valve, fitting, or manifold.[15]

Things You'll Need

Measuring and Making the Cut

- Measuring tape

- Pen or fine point marker

- Basic or ratchet-style PEX cutters

Cutting PEX Tubing to Remove Crimp Rings

- Pliers

- PEX cutter

- PEX crimp ring cutter

Installing PEX Tubing

- Compression ring

- PEX cutter or PVC cutter

- Expander tool

References

- ↑ http://groverelectric.com/assets/downloads/howto/26_How%20to%20Install%20Pex%20Pipe.pdf

- ↑ https://www.youtube.com/watch?v=twkse_IgtZ0&feature=youtu.be&t=60

- ↑ https://www.youtube.com/watch?v=GnszdQFnXEI&feature=youtu.be&t=84

- ↑ https://youtu.be/9Iu4aVqFAVE?t=48

- ↑ https://youtu.be/_Ss_8qz1nNg?t=34

- ↑ http://groverelectric.com/assets/downloads/howto/26_How%20to%20Install%20Pex%20Pipe.pdf

- ↑ https://www.familyhandyman.com/plumbing/pex-piping-everything-you-need-to-know/view-all/

- ↑ https://www.youtube.com/watch?v=GnszdQFnXEI&feature=youtu.be&t=70

- ↑ https://www.youtube.com/watch?v=GnszdQFnXEI&feature=youtu.be&t=84

- ↑ https://www.youtube.com/watch?v=KwnVbQuf4t8&feature=youtu.be&t=34

- ↑ https://www.youtube.com/watch?v=KwnVbQuf4t8&feature=youtu.be&t=34

- ↑ https://www.youtube.com/watch?v=KwnVbQuf4t8&feature=youtu.be&t=74

- ↑ https://www.askthebuilder.com/how-to-connect-pex-pipe/

- ↑ https://www.askthebuilder.com/how-to-connect-pex-pipe/

- ↑ https://www.askthebuilder.com/how-to-connect-pex-pipe/