This article was co-authored by James Hornof. James Hornof is a Master Electrician and the Owner and President of B & W Electric based in Denver, Colorado. With over two decades of experience in the electrical construction industry, James specializes in field installation, management, estimating, and design. He graduated top of his class in electrical trade school and studied Business Management at The Community College of Denver. James holds a Master Electrician license in Colorado, Wyoming, and Texas.

This article has been viewed 206,764 times.

Electrical conduit fittings form the outer covering for most electrical wiring from one point to the next. They shield the wires from the external environment so as to make the wire last longer and also to keep humans and pets safe from electric shocks or other such vulnerabilities. Electrical conduits are predominantly made of insulating and sturdy material for optimum functionality. Although it is best suited for a professional electrician to accomplish most electrical conduit fittings, there are some minor ones that you can easily do on your own.

Steps

-

1Choose the right material for installing electrical conduit fittings: The most preferred material is known as EMT (Electrical Metallic Tubing). EMT is very easy to install as you can effortlessly bend it and assemble it as per your needs. Also, you can conveniently take it off in case your wiring goes wrong somewhere. If you do not have it in your house, you can buy EMT from any of the electrical surplus stores for pretty cheap.[1]

-

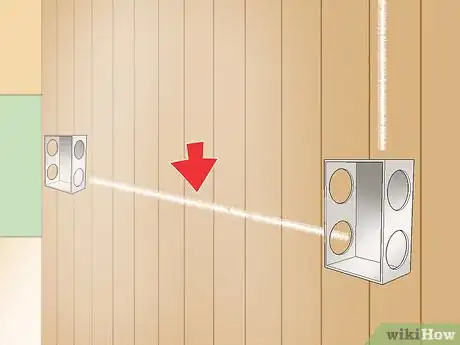

2Chalk out a wiring plan: Find out the location of the electrical boxes on your wall to trace the route of the conduit. Draw the path from the main power source to the electrical box.[2]Advertisement

-

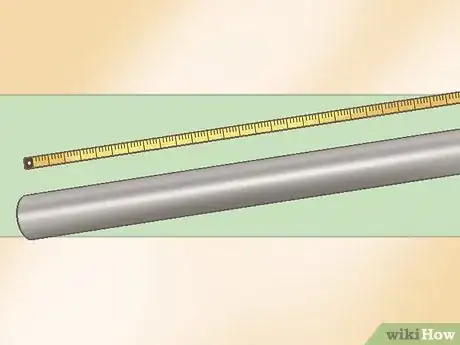

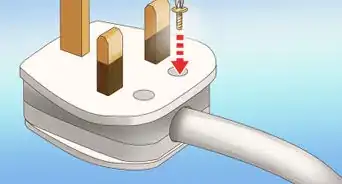

3Measure the amount of conduit that you would need: Make appropriate marks in pencil wherever you think the bends should be, and measure the total length of the conduit that would be needed to finish the entire electrical conduit fittings. Now cut the length that you just measured with a tool called hacksaw. The cut ends are likely to have burrs which can be removed using a deburring tool or with pliers.[3]

-

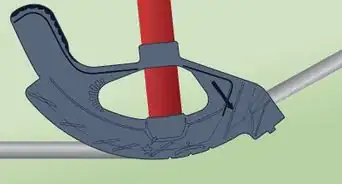

4Make the necessary bends: It is now time to make bends that you had marked on the pipe in the previous step. Owing to the easy flexibility of EMT, this should not be very difficult. Conduit benders come in handy for doing this bending.[4]

-

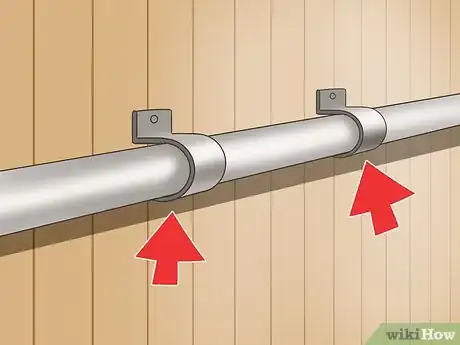

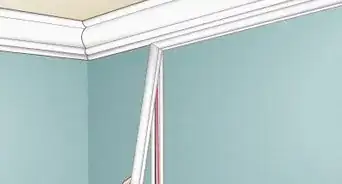

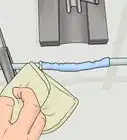

5Attach fittings to the wall: You can use screws and straps with either single or double holes, available at electrical surplus shops, to attach electrical conduit fittings to the wall.[5]

- Secure the conduit within three feet of where it connects to the electrical box.

-

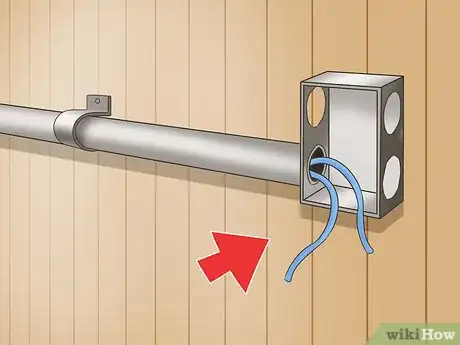

6Tape the ends and put the wires in place: Use a widely available fish tape and run it through the entire route of the conduit fittings you just installed. Fix together the ends along with the electrical wires with the same fish tape. Give a finishing touch by pulling all the wire in the pipe in their right place.

Community Q&A

-

QuestionWhat is required to couple two cut pipes?

Community AnswerA coupling is required. They come in two types: setscrew for dry applications and compression for wet and damp applications.

Community AnswerA coupling is required. They come in two types: setscrew for dry applications and compression for wet and damp applications. -

QuestionAre these steps in accordance with the PEC?

Community AnswerFor the most part, yes. However, you should never hang a strap as shown in the image. The screws securing the strap should be under the pipe when running horizontally, not above.

Community AnswerFor the most part, yes. However, you should never hang a strap as shown in the image. The screws securing the strap should be under the pipe when running horizontally, not above. -

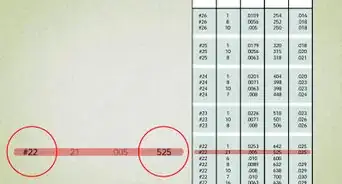

QuestionWhat is the appropriate spacing of the straps?

Community AnswerThe straps should be no more than 10 feet apart along the conduit and no more than three feet from any coupling or fitting.

Community AnswerThe straps should be no more than 10 feet apart along the conduit and no more than three feet from any coupling or fitting.

Warnings

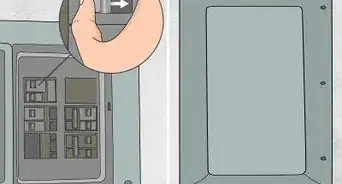

- If you are working on electrical wires that are attached to a power source, do remember to turn it off before you begin with your fittings. And if the wires are not already attached to the electrical supply, do not make attachments without first turning off the power source.⧼thumbs_response⧽

Things You'll Need

- EMT conduit

- Conduit bender

- Electrical boxes

- Elbows

- Setscrew couplings

- Single-hole or double-hole straps screws

- Offset fittings

- Setscrew

- De burring tool

- Hacksaw

- Screwdriver

- Electrical fish tape

- Electrical tape

- Tape measure

- Pencil

References

- ↑ https://www.familyhandyman.com/electrical/wiring/how-to-install-surface-mounted-wiring-and-conduit/

- ↑ https://www.familyhandyman.com/electrical/wiring/how-to-install-surface-mounted-wiring-and-conduit/

- ↑ https://www.bhg.com/home-improvement/electrical/how-to-install-metal-conduit/

- ↑ https://www.youtube.com/watch?v=PJOTR4MtHek

- ↑ https://www.bhg.com/home-improvement/electrical/how-to-install-metal-conduit/