14

Inventory of Innovative Indoor Smoke

Alleviating Technologies in Nepal

Year of dissemination

Cost

Quantity disseminated

Technological description

Early 90s onwards

NRs. 150 to 250 (but varies with size, base construction and

geographical location)

More than 200,000 from 2000 onwards were disseminated after

improvement in chimney and combustion chamber (by NICSP

supported by ESAP and coordinated by AEPC). The second pothole

raised model is more accepted because of better combustion and

suitability for using two bigger pots. These types of stoves cover

more than 85 per cent of total disseminated mud-brick ICS.

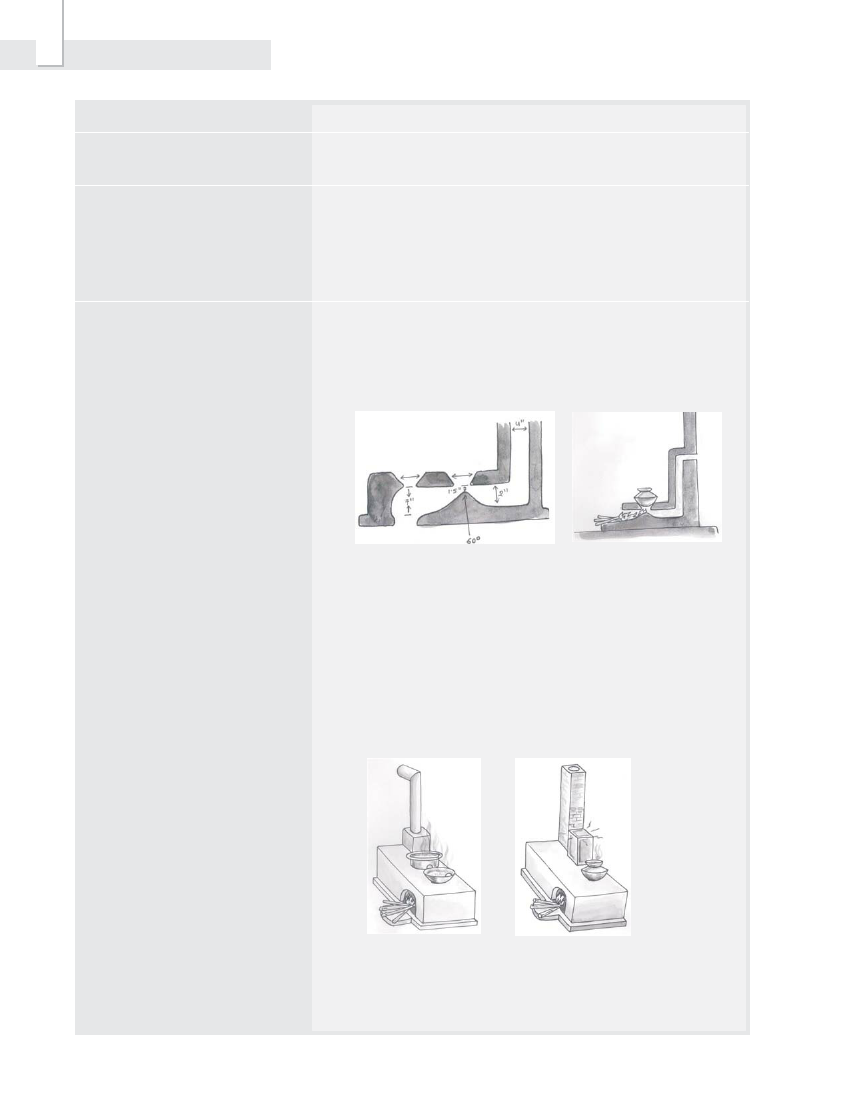

These stoves have only one fuel inlet below the first pothole. A baffle

is used at 60º to the horizontal and its peak point lies just below the

second pothole so that the flame and hot gas is directed to the

bottom of the second pot. The construction of baffle is shown in

Figure 3.7.

Figure 3.7: Baffle in two potholes mud-brick stove

Two potholes stove with grate facilitates increased combustion

efficiency with proper air circulation (air is pre-heated before reaching

to the fuel). The provision of grate makes the stove more suitable to

use agricultural residues and facilitate ash collection. It is

recommended to rotate pots while cooking to prevent smoke leakage.

Metal chimney can also be used in mud-brick stoves. In temperate

climate, metal tin is placed in the second pothole for space heating.

Figure 3.8 shows ICS with metal chimney and use of metal tin for

space heating.

Figure 3.8: Metal chimney and use of tin for space heating

If rear pothole is not used for cooking/heating, it is advisable to use

this pothole for water heating or to cover it as shown in Figure 3.9.