This article was co-authored by Gerber Ortiz-Vega. Gerber Ortiz-Vega is a Masonry Specialist and the Founder of GO Masonry LLC, a masonry company based in Northern Virginia. Gerber specializes in providing brick and stone laying services, concrete installations, and masonry repairs. Gerber has over four years of experience running GO Masonry and over ten years of general masonry work experience. He earned a BA in Marketing from the University of Mary Washington in 2017.

There are 9 references cited in this article, which can be found at the bottom of the page.

This article has been viewed 90,399 times.

If your home has concrete, you may notice holes forming due to strong weather or rodents. Most holes can be fixed with a quality mortar mix, although you should use one with a crushed stone aggregate to fill holes over 1 in (2.5 cm) deep. Treat holes as soon as you find them so you can prevent water and rodents from further damaging the concrete and getting into your home. Before attempting to fill a hole, clear out loose concrete and other debris. Then, mix the mortar, fill in the hole, and level it to blend it in with the surrounding structure. Concrete takes time to cure, so keep the patch moist for several days for a stronger fix. Patching concrete holes is a simple weekend project and it can help protect your home for decades.

Steps

Cleaning the Holes

-

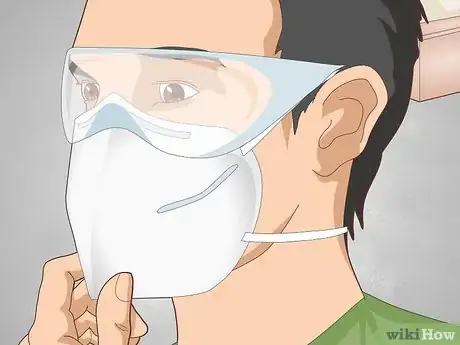

1Wear a dust mask and safety glasses before cleaning the concrete.[1] It is a dusty job, so always put on protective gear before working on the damaged area. Concrete releases plenty of dust when you chip it. That also means small fragments could come back toward your face while you work. Have rubber gloves available as well, although you won’t need them until you begin mixing new concrete.[2]

- If you’re working indoors, ventilate the area as much as possible to deal with the dust. Open nearby doors and windows. Turn on any available ventilation fans and vacuum up dust when you’re done.

- Since concrete can produce a lot of dust, consider protecting nearby areas with a plastic tarp.

-

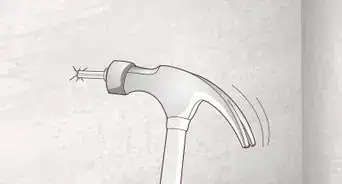

2Use a hammer and chisel to remove loose concrete from the hole. Knock away the cracked and crumbling concrete around the hole. Also, try to flatten out the bottom of the hole to create a stable, level surface for the new patching material. Since a thicker patch is more likely to last a long time, try to make the hole up to 1 in (2.5 cm) deep if it isn’t already deeper than that.[3]

- If the hole is already greater than 1 in (2.5 cm) deep, don’t try to make it deeper. Instead, clean it out and choose an appropriate patching compound.

- If possible, make the bottom part of the hole slightly wider than the top part. You can do this by holding the chisel diagonally to chip away at the bottom edges of the hole. Making the bottom part a little bigger helps lock the patch into the existing concrete.

- You could also use a circular saw with a masonry bit to cut out damaged concrete.[4]

Advertisement -

3Brush or vacuum loose debris out of the hole. For a simple way to clear out loose debris, scrub the concrete with a wire brush. If you have a shop vacuum, use it for a faster way to collect the debris. Make sure the hole is completely clear of debris before attempting to patch it.[5]

- Eliminate all debris so it doesn’t get in the way of the patching material. Anything left in the hole will weaken the patch!

-

4Wash the concrete with a cleaner if you need to flush out loose debris. Buy a commercial concrete cleaner and pour it in the hole. Scrub it with a wire brush to help work the cleaner into the remaining concrete. Check for any loose concrete kicked up by the brush and remove it.[6]

- Commercial concrete cleaners are very useful for preparing concrete. They eliminate tough stains, dirt, or debris that can weaken the new patch. Debris affects the concrete’s consistency, so the patching material may not bond properly or be as strong as it should be.

- If the concrete hole looks clean, you can just spray it with water.

-

5Rinse the concrete with clean water and let it dry. Spray it with water from a hose or pour water over it. Make sure all of the debris is gone. Then, soak up the excess moisture with clean rags or paper towels. Wait for any standing water to completely evaporate before attempting to patch the hole. This may take 30 minutes to an hour, depending on the weather and how much water is left.[7]

- Any water left over will weaken the concrete patch as much as loose debris would. Give it plenty of time to dry!

-

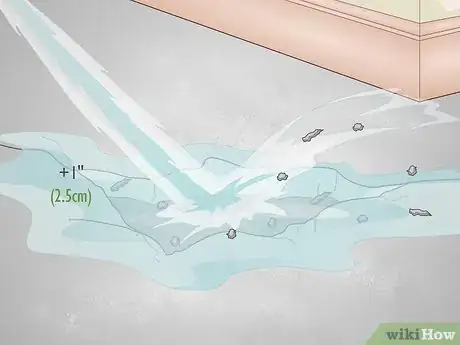

6Spray the hole with water if it’s more than 1 in (2.5 cm) deep. Removing the debris from a large hole is often a little challenging. In most cases, you can use a brush or vacuum to get most of the debris. If that isn’t an option, fill the hole with water. Spray it down with a hose or pour water into it until it overflows, flushing out the debris.[8]

- Remember to widen the hole by removing loose concrete first. Most of the time, this will allow you to brush or vacuum out the debris.

- Keep washing out the hole until you’re sure it looks clean. Watch for the water to stay clear without any debris in it. Then, soak up as much water as possible and let the hole air dry.

Mixing and Spreading Patching Material

-

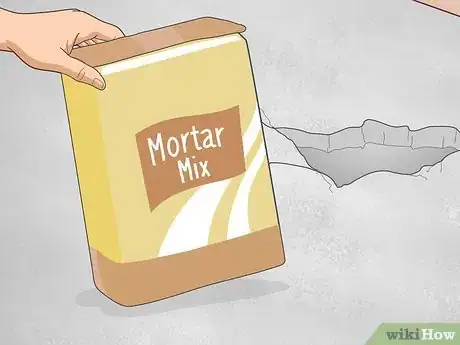

1Fill holes with a mortar mix instead of regular concrete. When you shop for store-bought concrete, you will see a variety of different options. New concrete can’t bond properly with the old concrete, so you will have to get something specifically meant for repairs. Select a mortar mix with sand for a hole less than 1 in (2.5 cm) deep and a mix with gravel for a hole deeper than that. The mortar mix often comes in 60 lb (27 kg) bags, which make about 1⁄3 cu ft (0.0094 m3) of concrete.[9]

- A 60 lb (27 kg) bag fills a hole about 1 ft (0.30 m) long, 3 ft (0.91 m) wide, and 2 in (5.1 cm) deep. Unless you’re doing many repairs, a single bag will most likely be enough.

- If you’re attempting to make your own mortar, combine 1 part Portland cement, 3 parts masonry sand or gravel, and water.

-

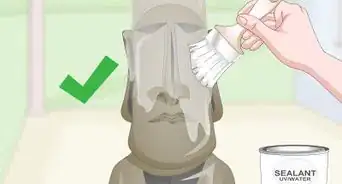

2Brush a bonding agent onto the concrete. A bonding agent is a liquid that helps join new and old concrete. Put on work gloves if you haven't already. Dip a paintbrush in and spread it throughout the hole. Coat the bottom and sides of the hole with an even, consistent layer.[10]

- Note that the bonding agent can often be added after you have poured the concrete into the hole. Check the manufacturer’s instructions for more information.

- You may also be able to mix the bonding agent in with the concrete. This is usually done by replacing 50% to 80% of the water with the bonding agent.

- If you don’t apply the bonding agent now, lightly dampen the concrete with a moist sponge. Make sure there isn’t any standing water in the hole.

-

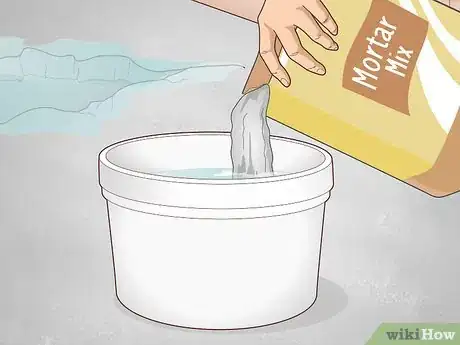

3Pour the mortar mix into a bucket filled with water. Add the water to the mixing bucket first to reduce the amount of dust released when you drop in the mortar. Generally, use about 10 fl oz (300 mL) of lukewarm water for every 5 lb (2.3 kg) of mortar mix you plan on using. If you use too much water, the mortar will be too soupy and won’t set properly.[11]

- Err on the side of caution when mixing the mortar. You can always add more water, but you can’t remove it. The only way to deal with a runny mix is to add more mortar.

- Remember to check the manufacturer’s recommendations on how much water to add. Factor in the liquid bonding agent if you plan on adding any to the mix.

- Make sure you're wearing safety glasses, a ventilated mask, long jeans, and gloves when mixing mortar.[12]

-

4Mix the mortar for 3 to 5 minutes until it forms a thick putty. Stir the mortar around in the bucket with a hoe or another tool. You can also use a paddle attachment, which is a metal mixing rod that plugs into the end of a power drill. Continue mixing the mortar while checking its consistency. It is ready for use once it reaches the consistency of a thick, spreadable peanut butter.[13]

- Make adjustments to get the mortar to the proper consistency. Add water gradually to thin it out, mixing it for a minute after each addition to check its consistency again.

-

5Layer mortar in the hole with a trowel. You can use a putty knife to spread the mixture over a small hole. Work the mixture into the hole with the tip of the tool. Cover the sides of the hole first, then begin filling the center of the hole. Try spreading the mortar about 1⁄4 in (0.64 cm) thick each time. If you wait for each layer to dry before adding the next one, you can create a stronger patch.[14]

- Layering mortar is only really useful if you’re working with a deep hole, such as one more than 1 in (2.5 cm) deep. If you’re fixing a shallow hole, you might as well finish it in one go.

- Keep the patching material roughly level with the surrounding concrete. Adding more than you need is okay. You will have a chance to eliminate the excess before it dries.

- Patching a vertical surface, such as a wall, is pretty much the same as patching a hole on the ground. Push the mortar deep into the hole at first, then add more layer by layer. It will stay in place.

Finishing and Curing Patches

-

1Drag a board over the hole to remove excess mortar. Select a board that is at least 1 ft (0.30 m) longer than the hole. Lay it across the hole on one side. Then, drag it over the hole. While dragging it, move it back and forth in a sawing motion to flatten the patch.[15]

- The board will collect excess mortar so you can smooth out the patch and keep it level with the surrounding concrete.

- For vertical surfaces, try dragging a board down over the hole and then going back over the patch with a trowel. If you can’t use a board, just use a trowel or float instead.

-

2Smooth out the remaining mortar with a trowel or float. If you have a float, which is a flat-bottomed tool designed for smoothing concrete, try using it on the mortar. Move the tool back and forth across the mortar a few times. After a few passes, the mortar patch will look flat and blend in well with the surrounding concrete.[16]

- Make sure the patch is level with the concrete around it. Use a wood board to remove any excess before smoothing the mortar out and letting it harden.

-

3Cover the patch with a plastic sheet to protect it from damage. The patch will be pretty vulnerable until it has had a chance to cure. Purchase a concrete insulation barrier, spread it out across the patch, and pin it in place. Weight it down with heavy objects like bricks. If you’re fixing a wall, use a waterproof tape to keep the sheet flat against the concrete.[17]

- Keep other people away from the concrete until it has had a chance to cure. Don’t let anyone walk or drive over it, for instance.

-

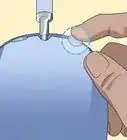

4Wait at least 6 hours, then mist the patch with lukewarm water. Quick-drying patching material usually takes about 4 to 6 hours to solidify. After it has become hard to the touch, lift up the plastic sheet. Use a spray bottle or a hose to lightly dampen the concrete with lukewarm water. Adding the water causes the concrete to continue curing, making the patch even stronger.[18]

- The drying time can vary depending on the weather and product used, so check the manufacturer’s recommendations before misting.

-

5Continue misting the concrete twice a day for at least 7 days while it dries. Many quick-drying compounds may cure at a faster rate, so consult the manufacturer’s instructions for more information. Set aside a certain time each morning and evening so you won’t forget to mist the patching material as it sets. Spray it each time with a light amount of lukewarm water. The patch continues to grow stronger as it cures.[19]

- Some products may require you to keep the patch covered for up to 28 days while misting each day. Even though this may seem like a long time, it is worth doing if the manufacturer recommends it.

- Once the concrete has finished curing, remove the plastic sheet and test it out. It should be level with the surrounding concrete and feel hard to the touch.

Warnings

- Concrete releases dust that can be irritating to breathe in. Always wear a dust mask, safety glasses, and work gloves.⧼thumbs_response⧽

Things You’ll Need

- Mortar mix

- Plastic bucket or wheelbarrow

- Hoe, shovel, or alternative mixer

- Trowel

- Wood board

- Hammer

- Chisel

- Wire brush or vacuum

- Clean water

- Hose

- Plastic concrete insulation sheet

- Misting bottle

- Bonding agent

- Paper towels

- Concrete cleaner (optional)

- Dust mask

- Safety glasses

- Work gloves

References

- ↑ Gerber Ortiz-Vega. Masonry Specialist & Founder, GO Masonry LLC. Expert Interview. 10 March 2020.

- ↑ https://www.bobvila.com/articles/how-to-fix-cracks-in-concrete/

- ↑ https://www.thisoldhouse.com/more/how-to-patch-concrete-floor

- ↑ https://www.concreteconstruction.net/how-to/repairing-bugholes_o

- ↑ https://www.concreteconstruction.net/how-to/repairing-bugholes_o

- ↑ https://www.concreteconstruction.net/how-to/repairing-bugholes_o

- ↑ https://www.thisoldhouse.com/more/how-to-patch-concrete-floor

- ↑ https://www.thisoldhouse.com/more/how-to-patch-concrete-floor

- ↑ https://www.bobvila.com/articles/how-to-fix-cracks-in-concrete/

- ↑ https://www.thisoldhouse.com/more/how-to-patch-concrete-floor

- ↑ https://www.youtube.com/watch?v=Wgq-DLrfKjU&feature=youtu.be&t=87

- ↑ Gerber Ortiz-Vega. Masonry Specialist & Founder, GO Masonry LLC. Expert Interview. 10 March 2020.

- ↑ https://www.youtube.com/watch?v=m3DUg2E9j6w&feature=youtu.be&t=83

- ↑ https://www.youtube.com/watch?v=mYz2tSILkGk&feature=youtu.be&t=137

- ↑ https://www.youtube.com/watch?v=m3DUg2E9j6w&feature=youtu.be&t=116

- ↑ https://www.thisoldhouse.com/more/how-to-patch-concrete-floor

- ↑ https://extremehowto.com/patching-repairing-concrete/

- ↑ https://extremehowto.com/patching-repairing-concrete/

- ↑ https://www.concreteconstruction.net/how-to/repairing-bugholes_o