This article was co-authored by Erik Bakirov and by wikiHow staff writer, Christopher M. Osborne, PhD. Erik Bakirov is a Cleaning Specialist at Room413 Cleaning in Los Angeles, California. Erik specializes in deep, move-in, and move-out cleaning services. Room413 matches homeowners with reliable and trustworthy cleaning services. They also promote environmentally friendly cleaning products.

There are 9 references cited in this article, which can be found at the bottom of the page.

This article has been viewed 122,639 times.

Polished concrete has a modern, sophisticated appearance, and the polishing process can improve the overall condition of the material. The process is fairly straightforward, but it does require plenty of physical labor and time. You must clean and patch the surface, grind it smooth with several passes of a concrete grinder, buff it to bring out the shine, and apply a sealer to protect your work. Note that while there are some similarities to polishing a concrete countertop, this article focuses on polishing concrete floor surfaces.

Steps

Cleaning and Patching the Surface

-

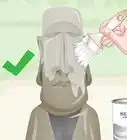

1Clean the entire surface with soap, water, and a bristle brush. Dip your bristle brush into a bucket of warm water mixed with a typical household cleaner and scrub the concrete thoroughly.[1] Rinse the area with clean water and let it air dry.[2]

- For stubborn stains, try only one of the following at a time: hydrogen peroxide, ammonia, or TSP (trisodium phosphate). Never mix any of these. Use the same cleaning process as before, but be sure to wear protective gloves and eyewear. Keep the area well-ventilated, too.

- To avoid working on your hands and knees, get a push broom-style bristle brush with a handle.

-

2Inspect the concrete closely for damage and hazard spots. Cleaning the surface first gives you a better look at the concrete. Scan it for large cracks or potential hazards, such as protruding pieces of metal. Identify these with temporary marking paint so you can address them separately before you start grinding.[3]

- A protruding nub of metal reinforcing bar, for example, must be chipped and cut out, and then the area must be repaired, before you start grinding the concrete. Hire a professional if you don’t know how to do this repair yourself.

Advertisement -

3Repair any cracks with a concrete filler or patch material. For cracks up to 0.25 in (0.64 cm) wide, buy a concrete crack filler that applies with a caulk gun. Squeeze it into the crack and smooth it with your finger or a paint scraper. For wider cracks, choose a vinyl concrete patch material. Use a trowel to both fill the crack with the patch material and smooth it out even with the surface.[4]

- Use a wire brush to remove any debris from inside the cracks before patching them. Sweep up the removed debris.

- Let the product cure fully as per the time listed in the package instructions. After the filler or patch has cured, sweep up any debris on the floor in the repair area.

Smoothing the Surface with a Grinder

-

1Test the concrete with MOHS hardness picks before renting a grinder. Choose a representative area of the concrete, hold the #9 pick like a pencil, and apply the same pressure you would to draw a roughly 2 in (5.1 cm) pencil line on the concrete. Look and feel for a scratch. Keep working your way down the pick numbers (#8, #7, etc.) until you reach a pick that doesn’t leave a scratch.[5]

- If, for example, the #7 pick scratches the concrete but the #6 pick doesn’t, estimate that the concrete has a MOHS (Measurement of Hardness Scale) rating of 6.5. The higher the number, the harder the concrete.

- Buy a set of MOHS hardness picks online or at a home center.

- When you go to rent a concrete grinder, the set of grinding discs that you rent with it may vary based on whether your concrete is soft (5.5 or lower), medium (6.5), or hard (7.5 or higher).

-

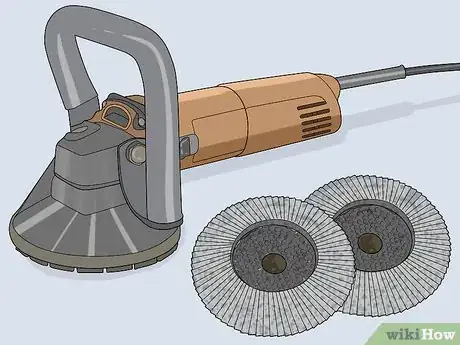

2Rent a concrete grinder with a set of metal-bonded diamond discs. Look for concrete grinders to rent at hardware stores and tool rental retailers. The set of concrete grinding discs that come with the grinder should range from about 40-grit to 3000-grit. If given the option, choose a set of grinding discs that specifically suits either soft, medium, or hard concrete (based on your MOHS testing).[6]

- You must use a specialized tool to grind concrete; a standard sander won’t do the job.

- The grinding discs must be metal-bonded diamond discs. Non-diamond discs aren’t hard enough to grind down the concrete properly.

- Before agreeing to rent the grinder, make sure that it feels comfortable enough for you to use. Get instructions on how it works, and ask if you can start it up, if possible.

- Renting a grinder can cost as much as $1000 USD per week, so this project may not be especially cost-effective if you're only working with a small concrete surface. It may actually be cheaper to hire a pro to do the job.

-

3Put on protective gear before handling the grinder. Wear a dust mask, thick gloves, safety goggles, and ear plugs. The grinder is loud, creates a lot of dust, and can cause serious injury if used improperly. Therefore, consider the user’s manual to be another piece of required safety equipment.[7]

- Wear work shoes with a good grip. No-slip footwear can help prevent accidents caused by sliding, slipping, or falling over.

- If you are working in an area currently undergoing other construction, wear a safety helmet. In fact, you may want to wear a helmet in any case.

-

4Grind the surface in half-circle motions with a 40- or 80-grit disc. Attach the disc according to the grinder’s instructions. To remove sealer, stain, or other contaminants that wouldn't wash off, start with a 40-grit grinding disc. Otherwise, use the 80-grit disc. Turn on the grinder and use the handle to turn the disc back and forth in half circles while slowly moving forward. Go slowly and work over the surface evenly.[8]

- Start from one corner of the surface and work your way out and over to the opposite corner.

- Remember that lower grit values indicate coarser discs. In other words, 40-grit discs are coarser than 80-grit discs.

- Rely on the product instructions for specific guidance on using your chosen grinder.

-

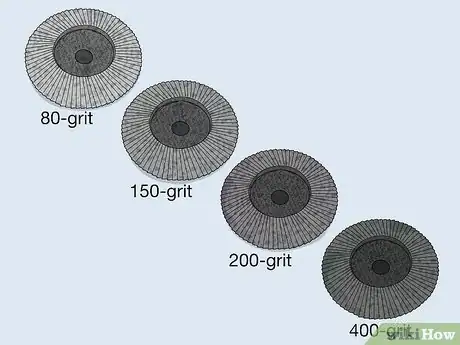

5Repeat the grinding process using 80-grit through 400-grit discs. Pass over the concrete with each disc in your set. For example, go through the following progression: 40-grit, 80-grit, 150-grit, 200-grit, and 400-grit. Pass over the entire surface with each new disc, working perpendicular to your last pass—in other words, start at an adjacent, not opposite, corner, based on where you started the previous pass.[9]

- For example, visualize a square concrete surface from above. If you made the first pass from the top left to the bottom right corner, make the second pass from the top right to the bottom left corner.

- Each pass with a new disc will buff away the scratches created during the previous pass, and in turn create finer scratches to be buffed away by the next pass.

-

6Spray on a densifier after the 80-, 200-, or 400-grit grinding pass. Apply the densifier, a liquid chemical hardener, over the entire surface according to the product instructions. Spraying it on makes the concrete less permeable and less likely to form powdery dust on its surface. The best time to densify the surface depends on the hardness of the concrete, as per the results of the MOHS test you conducted.[10]

- For soft concrete, apply the densifier after using the 80-grit disc. For medium concrete, use it after the 200-grit pass. For hard concrete, wait until after the 400-grit pass.

- To apply most brands of densifier, pour the product into a small sprayer. Use the nozzle of the sprayer to coat the entire concrete surface, then let it dry before continuing.

-

7Make the final grinding pass with the 3000-grit disc. Work over the entire concrete surface as before, moving from one corner to the diagonally opposite one. The grit on this disc is so fine that it will actually begin the process of polishing the surface.[11]

- You can skip straight to polishing if you wish, but using the 3000-grit disc will give the finished concrete more of a high-gloss appearance.

-

8Vacuum all dust and debris off the concrete surface. Grinding concrete produces plenty of dust and debris. After you finish the last pass with a grinding disc, suck up as much material as possible with a wet-dry vac.[12]

- Some concrete grinders come with an integrated vacuum, which you should definitely use while grinding. Even in this case, though, use a wet-dry vac when you’re done grinding.

- Vacuuming the surface between disc passes is fine but not typically necessary. One thorough vacuuming before you buff the concrete should suffice.

Buffing and Sealing the Surface

-

1Attach a burnishing pad to the grinder and pass it over the concrete. Remove the final grinding disc from your concrete grinder and put on a burnishing pad, once again following the product instructions. Turn on the grinder and go over the entire concrete surface with this pad, using the same corner-to-corner, half-circle technique as before.[13]

- The burnishing pad will buff the concrete and make it notably smooth.

- You should be able to rent a burnishing pad when you rent the grinder and discs. However, if you don’t have a burnishing pad for your concrete grinder, or if the machine doesn't have an appropriate setting for a burnishing pad, rent and use a low-speed brush-style buffer instead.

-

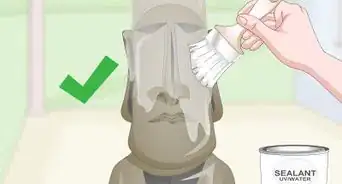

2Apply a thin coat of concrete sealer with a roller or sprayer. Choose a water-based or solvent-based concrete sealer and follow the manufacturer's instructions when applying it. If it needs to be rolled on, fill a paint pan and use a paint roller to apply a thin coat over the surface. If it must be sprayed on, fill the recommended type of sprayer as directed and apply a light, even coating over the concrete.[14]

- Sealers protect the concrete against grease, dirt, and other stains. Moreover, using a glossy sealer should give the polished concrete more of a sheen.

- Apply concrete sealer only during dry conditions, and make sure that the air temperature remains above 50 °F (10 °C) during the application and for 24 hours afterward.

-

3Apply a second sealer coat 2-4 hours after applying the first. Give the sealer at least 2 hours to dry—if it’s still tacky to the touch, wait another 2 hours (or more if necessary). Roll or spray on the second coat of sealer using the same technique as before. However, work in a perpendicular direction—that is, start at an adjacent (not opposite) corner to where you started the first coat.[15]

- Make sure the second coat is thin and even just like the first.

- Give the second coat 2-4 hours to dry before proceeding.

-

4Burnish the surface again to enhance the glossy finish. Once the sealer is dry to the touch, pass over the sealed surface with the burnishing pad or buffer. Go in a perpendicular direction from your previous burnishing pass. Work slowly and thoroughly, covering the entire surface at an even pace.[16]

- When you finish this final pass, the concrete should look as smooth and glossy as finished stone.

-

5Wait at 24-72 hours before using the finished surface. Allow the final coat of sealer to completely dry before walking on the surface or otherwise using it. The exact amount of time varies by manufacturer, but will usually be between 24 and 72 hours.[17]

- After you wait the appropriate amount of time, the polished concrete is finished and ready for active use.

Expert Q&A

-

QuestionWhat should you clean concrete countertops with?

Erik BakirovErik Bakirov is a Cleaning Specialist at Room413 Cleaning in Los Angeles, California. Erik specializes in deep, move-in, and move-out cleaning services. Room413 matches homeowners with reliable and trustworthy cleaning services. They also promote environmentally friendly cleaning products.

Erik BakirovErik Bakirov is a Cleaning Specialist at Room413 Cleaning in Los Angeles, California. Erik specializes in deep, move-in, and move-out cleaning services. Room413 matches homeowners with reliable and trustworthy cleaning services. They also promote environmentally friendly cleaning products.

Cleaning Specialist Regular dish soap and water work best to get the countertop clean. Dust and remove any dry debris from the countertop before beginning. Apply dish soap and water to a wet rag, and give your counters a good scrubbing. Do not use any abrasive material to clean the countertop.

Regular dish soap and water work best to get the countertop clean. Dust and remove any dry debris from the countertop before beginning. Apply dish soap and water to a wet rag, and give your counters a good scrubbing. Do not use any abrasive material to clean the countertop. -

QuestionHow to clean a stain on polished concrete?

BECOSANCommunity AnswerIf the stain has already penetrated the concrete, I'm afraid there's not much we can do. There are some products that absorb grease from the pores, but they don't work really well. To prevent this, it is better to have a polished and sealed concrete.

BECOSANCommunity AnswerIf the stain has already penetrated the concrete, I'm afraid there's not much we can do. There are some products that absorb grease from the pores, but they don't work really well. To prevent this, it is better to have a polished and sealed concrete. -

QuestionCan you stain the polished concrere floor after it has been sealed?

BECOSANCommunity AnswerNo, in case you want to stain the concrete it needs to be done before sealing process. The stage most recommended is when the pores are open (after sanding the surface).

BECOSANCommunity AnswerNo, in case you want to stain the concrete it needs to be done before sealing process. The stage most recommended is when the pores are open (after sanding the surface).

Warnings

- Only polish and seal concrete that has been completely cured. Wait at least 28 days after pouring new concrete before beginning this process.⧼thumbs_response⧽

Things You'll Need

- MOHS hardness pick set

- Household detergent

- Bristle brush

- Concrete crack filler

- Dust mask

- Safety goggles

- Ear plugs

- Gloves

- Concrete grinder

- Grinding discs of varying grits

- Liquid densifier

- Spray applicator

- Wet-dry vacuum

- Burnishing pad or low-speed buffer

- Concrete sealer

References

- ↑ Erik Bakirov. Cleaning Specialist. Expert Interview. 7 January 2021.

- ↑ http://www.bobvila.com/articles/how-to-clean-concrete/#.VXB4Us9Viko

- ↑ http://www.bobvila.com/articles/how-to-clean-concrete/#.VXB4Us9Viko

- ↑ https://www.concretenetwork.com/products-polishing/how-to.html

- ↑ https://youtu.be/d7lSC-_4vok?t=32

- ↑ https://www.bobvila.com/articles/how-to-polish-concrete/#.VXB29c9Vikp

- ↑ https://www.concretenetwork.com/products-polishing/how-to.html

- ↑ https://www.concretenetwork.com/products-polishing/how-to.html

- ↑ http://www.lifeofanarchitect.com/polishing-concrete-floors/

- ↑ http://www.concretenetwork.com/products-polishing/densifiers/application.html

- ↑ https://www.concretenetwork.com/products-polishing/how-to.html

- ↑ https://www.concretenetwork.com/products-polishing/how-to.html

- ↑ http://www.bobvila.com/articles/how-to-polish-concrete/#.VXB29c9Vikp

- ↑ http://www.concretenetwork.com/concrete/maintaining/sealingplain.htm

- ↑ http://www.concretenetwork.com/concrete/maintaining/sealingplain.htm

- ↑ https://www.bobvila.com/articles/how-to-polish-concrete/#.VXB29c9Vikp

- ↑ https://www.concretenetwork.com/products-polishing/how-to.html

About This Article

To polish concrete, start by grinding the surface with a concrete grinder, which you can rent at a hardware store. Once you’ve finished grinding, vacuum up the debris, and go over the entire surface with a buffer to smooth it out. Then, apply 2 thin coats of sealer to the concrete, waiting 2 to 4 hours between each coat so it can dry. Finally, go over the concrete surface one more time using a burnishing pad or buffer. For tips on how to wash and repair your concrete before polishing it, keep reading!