This article was co-authored by wikiHow Staff. Our trained team of editors and researchers validate articles for accuracy and comprehensiveness. wikiHow's Content Management Team carefully monitors the work from our editorial staff to ensure that each article is backed by trusted research and meets our high quality standards.

There are 7 references cited in this article, which can be found at the bottom of the page.

This article has been viewed 20,691 times.

Learn more...

Polypropylene, also known as PP, is a super versatile plastic that’s used in a variety of products such as plastic containers, toys, furniture, car parts, and even medical implants. If something made of polypropylene is damaged or cracked, it can be repaired, but it needs to be done with polypropylene glue. To help you repair your polypropylene, we’ve answered some of your most common questions about the process.

Steps

How do you fix a hole in polypropylene?

-

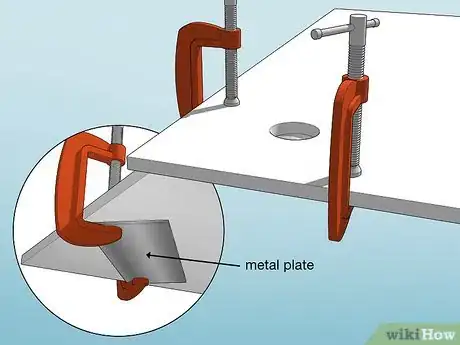

1Clamp a metal plate on the backside of the hole. Take a flat metal plate and attach it to the other side of the hole so it acts as a backing board that will keep the plastic contained when you weld it. Use a clamp to hold it securely in position.[3]

-

2Fill the hole with a polypropylene welding rod. Use a heat gun to warm the polypropylene welding rod so it’s pliable and curl it inside of the hole. Then, hold the heat gun over the plastic to melt it and cause it to expand and fill in the hole. Use a soldering iron to cut off any excess plastic and run the soldering iron over the plastic in the hole to smooth it out.[4]

- You must use a polypropylene welding rod to create an effective bond that will seal the hole.

-

3Allow the plastic to cool and then remove the metal plate. Wait until the plastic is completely cool to the touch and hardened. Then, unclamp and remove the metal plate and you’re good to go![5]

Warnings

- Welding can cause burns and be a fire hazard if it isn’t done properly. Make sure you know what you’re doing and you wear protective equipment.⧼thumbs_response⧽

References

- ↑ https://www.loctite-consumer.co.uk/en/how-to-guide/home-repairs/polypropylene-glue-a-super-strength-adhesive-for-tough-jobs.html

- ↑ https://www.plasticweldingtools.co.nz/how-to-weld-plastics/

- ↑ https://youtu.be/jveoSHwxsm8?t=17

- ↑ https://youtu.be/jveoSHwxsm8?t=31

- ↑ https://youtu.be/jveoSHwxsm8?t=48

- ↑ https://northernnester.com/best-glue-for-plastic/

- ↑ https://expandusceramics.com/qa/can-you-glue-polypropylene.html