This article was co-authored by Gerber Ortiz-Vega. Gerber Ortiz-Vega is a Masonry Specialist and the Founder of GO Masonry LLC, a masonry company based in Northern Virginia. Gerber specializes in providing brick and stone laying services, concrete installations, and masonry repairs. Gerber has over four years of experience running GO Masonry and over ten years of general masonry work experience. He earned a BA in Marketing from the University of Mary Washington in 2017.

This article has been viewed 84,050 times.

Concrete steps are exposed to the elements every day. After time, the steps can crack or begin to break apart. Cracked steps pose a potential safety risk to people entering or leaving your home and must be repaired. Use these instructions to repair concrete steps.

Steps

-

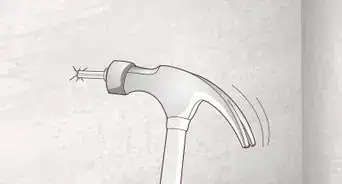

1Clean the damaged portion of the concrete step. Remove all loose gravel, sand, dirt, and cement with a clean, stiff wire brush. You can also tap lightly with a hammer or use a hammer and chisel.[1]

- If the day is going to be hot, work in the morning, and then moisten the cement throughout the day.

-

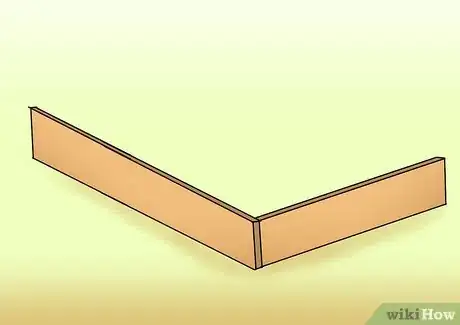

2Make a form. Screw 2 short pieces of 1 inch by 6 inch (2.54 cm by 15.24 cm) lumber together at a 90-degree angle to form an "L" shape.[2]

- The form can also be held together using several long pieces of duct tape.

Advertisement -

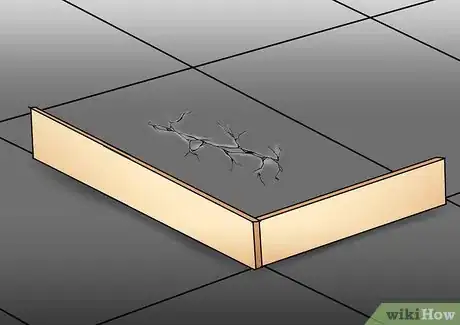

3Align the wood form. Place the wood form against the damaged corner of the concrete step so it is flush with the top of the step. Tape the form to the step firmly with duct tape.[3]

-

4Lubricate the form. Spray a coat of cooking oil spray on the inside of the wood form to prevent the wood from sticking to the new concrete.

-

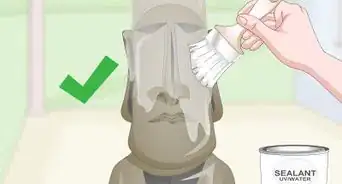

5Apply bonding liquid. Use a paint brush to apply a thick coat of latex bonding liquid on the damaged portion of the concrete step were you will be applying the new concrete.[4]

-

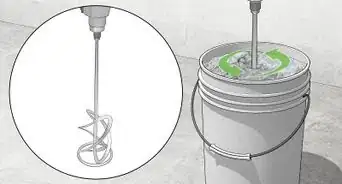

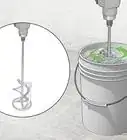

6Prepare quick-setting cement. Mix a small amount of quick-setting cement in a plastic bucket according to the instructions on the packaging. Make sure to add enough water, otherwise you won't be able to mix it properly. Do not use pre-mixed vinyl cement repair because it shrinks and will not hold weight. These vinyl fillers are best used to fill holes in stucco walls where no one is walking over them. "Cement-all", that is $22 per bag, does not need a bonding agent, and can be driven over in 60 minutes with an automobile.

- When you are mixing cement, wear safety gloves, a safety mask, and clothes that cover your skin (like jeans).

-

7Dampen the area. Moisten the area where you are going to be adding the new cement so that the existing concrete will not draw the moisture out of the wet cement, making it less likely to harden properly.

-

8Apply the cement. Use a pointed trowel to scoop the cement onto the damaged portion of the step and press it into the wood form. Overfill the wood form slightly.

-

9Smooth the newly laid cement. Use the flat side of the trowel to smooth the cement so it is flush with the remaining portion of the step. Don't be afraid to apply pressure. Pressure will fill holes and make it more level.

-

10Allow the concrete to dry overnight.

-

11Remove the duct tape and the wood form.

-

12Keep the cement moist. Use a spray bottle to moisten the new concrete patch 2 or 3 times a day for 3 days. Then moisten the patch twice daily for a week.

- This is needed to make the cement cure slower. If it gets dry too fast, it is more likely to crack.

Community Q&A

-

QuestionDoes an external repair need to be covered to protect it from the rain?

Community AnswerYes, cover the cement with plastic or plywood. If you use fast drying cement, it will not need to be covered because most fast drying cements cure within 1 hour.

Community AnswerYes, cover the cement with plastic or plywood. If you use fast drying cement, it will not need to be covered because most fast drying cements cure within 1 hour.

Things You'll Need

- Wire brush

- 1-inch by 6-inch (2.54 cm by 15.24 cm) lumber

- Duct tape

- Drill and screws (optional)

- Cooking oil spray

- Latex bonding liquid

- Quick-setting cement

- Plastic bucket

- Plastic spray bottle

- Hand sledgehammer, if needed

- Trowel

References

- ↑ https://www.todayshomeowner.com/video/how-to-repair-and-resurface-concrete-steps/

- ↑ https://www.todayshomeowner.com/video/how-to-repair-and-resurface-concrete-steps/

- ↑ https://www.dummies.com/home-garden/exteriors/how-to-repair-broken-concrete-step-corners/

- ↑ https://www.dummies.com/home-garden/exteriors/how-to-repair-broken-concrete-step-corners/

- http://www.thisoldhouse.com/toh/skill-builder/0,,466378,00.html